18072885002

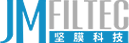

Silicon carbide ceramic tubular membrane brine refining technology is a mature process, the use of silicon carbide ceramic tubular membrane material has a strong resistance to contamination, acid and alkali resistance, as well as strong anti-mechanical erosion performance characteristics, and the use of high-efficiency “staggered flow” filtration, can provide stable and reliable long-term high-quality brine, with other refining and filtration technology is difficult to reach the efficiency and advantages. It can provide stable and reliable high quality brine for a long time, which has the advantages of other refining and filtration technologies.The crude brine undergoes saltification, refining reaction, crude filtration, and tubular membrane filtration to obtain refined brine that meets the primary brine product index.

I. Silicon Carbide Membrane Brine Refining Process Flow Chart

II. silicon carbide membrane brine refining technology features

1, Narrow aperture distribution of membrane element, wrong flow filtration, high separation precision;

2, acid and alkali resistance, solvent resistance, oxidation resistance, high temperature resistance;

3, high mechanical strength, good abrasion resistance, scouring resistance;

4, good thermal stability, stable material properties;

5, high permeability flux, long service life, strong regeneration capacity;

6, anti-microbial degradation and erosion, anti-pollution ability;

7, short process flow, small equipment footprint, more economical investment;

8、Stable solid content of the discharged concentrate;

9, fully automated process design;

10, fully closed operation process;

11, energy saving, low operating costs.

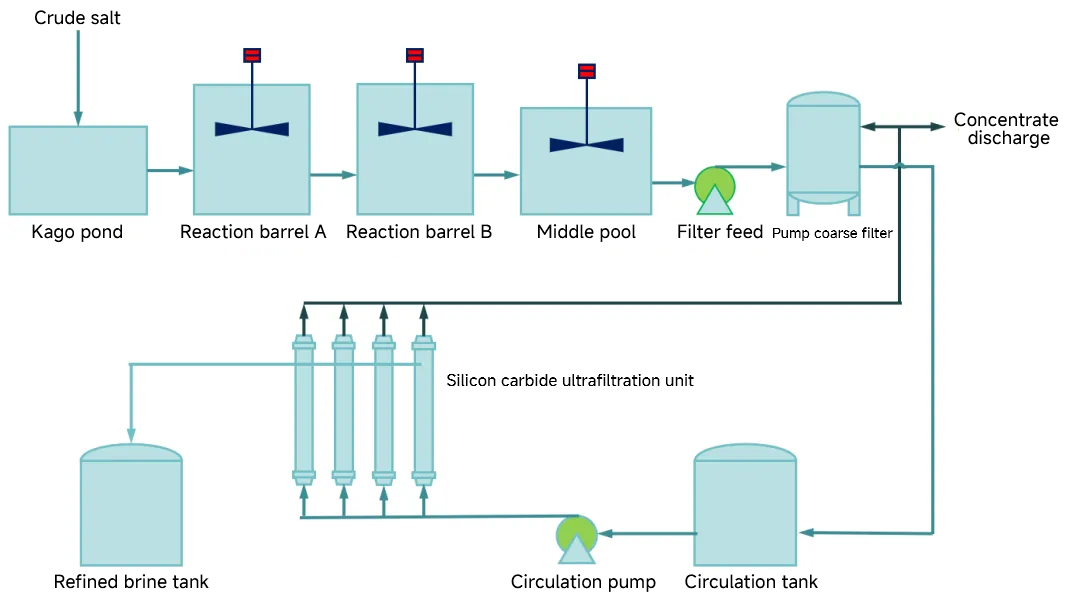

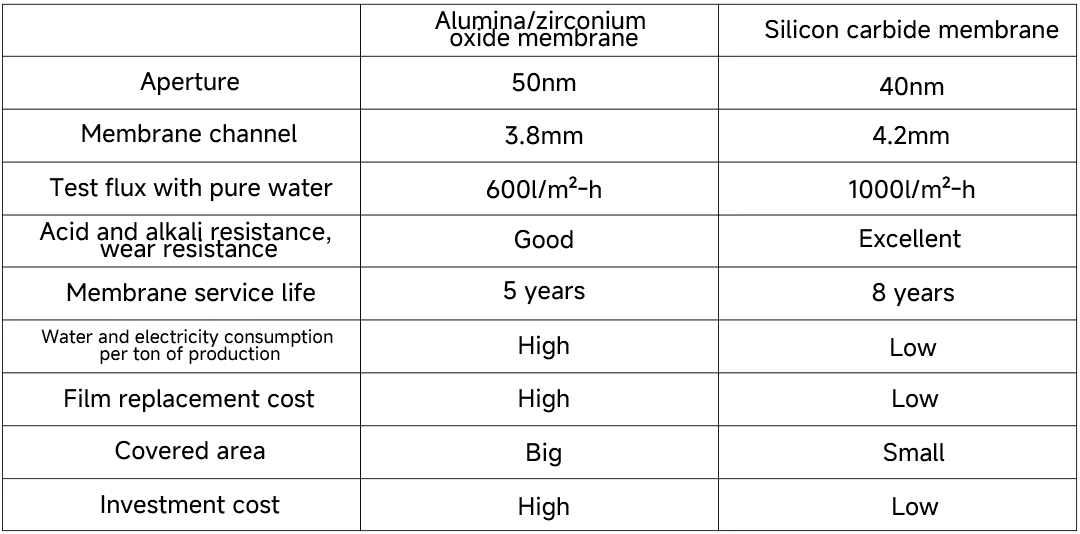

III. silicon carbide membrane and other membrane brine refining process comparison

Table 1 Comparison of Brine Refining Processes with Silicon Carbide and Organic Membranes

Table 2 Comparison of Silicon Carbide Membrane and Traditional Ceramic Membrane Brine Refining Processes

IV. Silicon Carbide Membrane Brine Refining Application Cases

240 m³/h Primary Brine Refining Organic Membrane System Conversion to Silicon Carbide Membrane System

Supporting Tubular Ceramic Membrane Elements

Application of Silicon Carbide Membranes in the Primary Brine Unit of a Ningbo Chlor-Alkali Company. Due to the high maintenance costs associated with the existing organic membrane equipment reaching the end of its service life and limited land availability, the company installed a single 240 m³/h silicon carbide membrane unit in the first phase of its brine refining renovation in July 2021. This reduced investment, land occupation, and operating costs by half compared to traditional ceramic membrane processes. After three months of operation, water production was stable and brine performance was excellent. Three additional silicon carbide membrane units were installed in the second phase in February 2023.

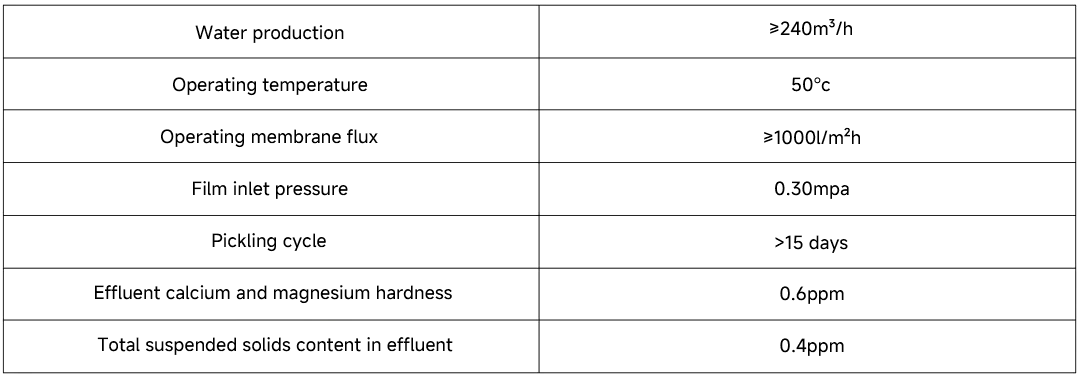

Table 3 Operating Data Parameters