18072885002

Water is one of the indispensable and important resources for human survival. Various chemical reactions in the structure of the human body must also be carried out normally with the participation of water. The quality of the water quality directly affects our health. Healthy and safe water can enhance the human immune capacity, which is conducive to promoting cell metabolism.

Silicon carbide membrane is a high purity silicon carbide fine powder after recrystallisintering technology made of high throughput, corrosion resistance, easy cleaning, long life of high precision microfiltration & ultrafiltration grade membrane separation products, the highest filtration accuracy can reach 20 nanometers.

Characteristics of the silicon carbide membrane:

● High flux, pure water flux 3000 LMH @ 25℃

● Easy cleaning, efficient cleaning (save drugs and reduce the production of cleaning wastewater)

● Nanobubble generator strengthens the treatment in the drinking water process section according to the characteristics of nanobubble

● The application process of nanobubble + coagulation improves the removal efficiency and operation stability of pollutants.

● The application process of nanobubble + ozone disinfection replaces chlorine disinfection, which improves the disinfection efficiency, reduces the dosage of disinfectant, and makes the disinfection longer and smaller.

Characteristics of the nanobubbles:

● Long stay in water (2-3 months)

● Surface with strong negative charge (attract positively charged particles and settle, improve the transparency of water)

● High mass transfer efficiency (oxygen transport rate above 85%)

● Strong oxidation, releasing free radicals upon rupture

Short process silicon carbide ultrafiltration membrane treatment process uses our silicon carbide ceramic flat sheet ultrafiltration system, can combine ozone contact oxidation tank and ultrafiltration system into one device, greatly saving the area and shorten the process, with a more flexible process design. The combination of the process refinement and the product advantages makes the equipment rarely polluted during operation, reduce the operation and maintenance burden of on-site personnel, reduce cost and increase efficiency.

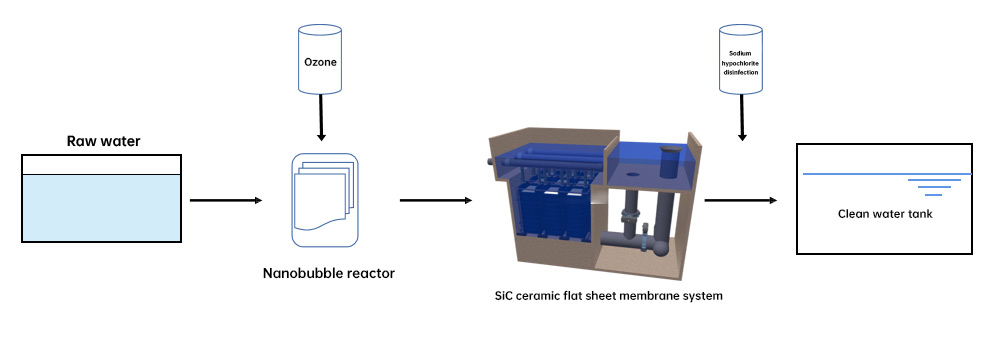

Process flow description:

Raw water flows from the mountain into the ceramic membrane treatment equipment, and nanobubble generator is installed on the inlet pipe and fed into ozone to produce fine bubble water containing ozone. On the one hand, it relies on odor oxidation to decompose organic matter in the water, and on the other hand, it alleviates membrane pollution through sterilization and friction. The incoming water containing ozone nanobubbles flows to the membrane pool along the pipeline, and the silicon carbide flat sheet membrane is installed with the membrane tank, and the clean water is extracted from the membrane hole under the suction action of the cleaning water pump. After that, sodium hypochlorite was added to the membrane production pipe to disinfect the water purification and sent into the water distribution network.

During the operation of the ceramic ultrafiltration membrane system, a periodic backwashing is required to remove the filter cake layer from the membrane surface.

| Device information | |

| Integrated drinking water equipment | Model |

| Interface caliber | Water inlet DN32, water outlet DN50, sewage DN50 |

| Rate of flow | 5m³/hr |

| Operation mode | Automatically execute |

| Membrane core | SiC |

| Frame material | Anticorrosion carbon steel / Stainless steel |

| Pipeline material | UPVC |

| Control valve | Automatically execute |

| Size | L2600*W15610*T2220mm |

| Handling capacity | 5m³/hr |

| Working voltage | 380V |

| Power | 1.5-5.5kw |

| Working pressure | 0~-30kPa |

| Membrane precision | 20-100nm |