18072885002

Product Description

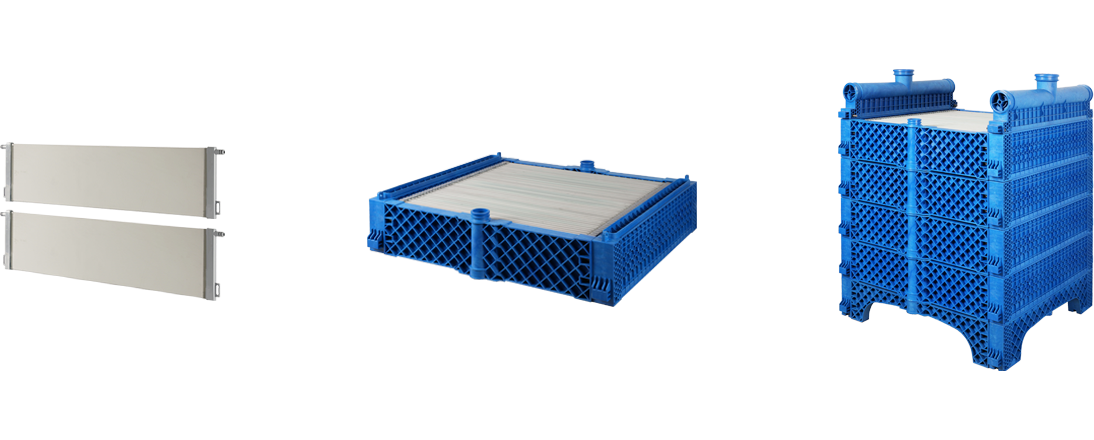

Our silicon carbide flat sheet membrane module is a modular, scalable filtration unit consisting of a glass fiber reinforced plastic shell and a flat ceramic membrane. The module integrates a water production channel internally while being able to withstand high pressure. Our membrane modules have been simulated by CFD fluid mechanics and tested in practice to achieve the best performance of flat sheet ceramic membranes. The entire shell and all accessories do not contain any metal, so it can be used in the harshest applications while extending its service life. In addition, no surrounding frames or hose connections are required between membrane modules.

• Operation mode: dead-end operation

• Filtration principle: external pressure operation, negative pressure suction

Product features and advantages

• The core material silicon carbide has better hydrophilicity, higher porosity, excellent cleaning recovery ability, and resistance to oil pollution.

• Less filtration area is required for high-throughput operation, saving a lot of cost expenditure.

• Good anti-pollution performance, resistance to water inlet fluctuations, and stable flux in long-term operation.

• Good chemical stability, acid and alkali resistance, strong oxidant resistance, high temperature resistance, organic solvent resistance, cleaning resistance, and easy recovery of flux after cleaning.

• Suitable for seawater and other challenging applications without any risk of corrosion issues.

• Since there is no surrounding frame, the membrane module is fully modularized, so the number of membrane modules per tower can be changed at any time to optimize project costs or increase future processing capacity.

• The most compact design, no need to set up independent water production pipelines, and the membrane system is highly integrated.

• Competitive investment cost and excellent life cycle.

◎ Membrane element parameters

|

Effective filtration area |

0.177 m2 |

|

Support layer material |

Silicon carbide |

|

Filter layer material |

Silicon carbide |

|

Filtration accuracy |

0.1μm |

|

Dimensions |

L600×W145×T6mm |

|

Pure water flux |

≥3000L/(m2·h·bar)@25℃ |

|

Operating temperature |

5-65℃ |

|

pH |

2-12 |

|

Maximum operating pressure |

-0.7bar |

|

Maximum backwash pressure |

1.2bar |

|

Cleaning method |

Backwash/air scrubbing/spraying/chemical cleaning |

◎ Membrane module parameters

| Membrane module size |

L750×W715×H160mm |

|

Dry weight |

44.8kg |

|

Membrane shell material |

NORYL™ resin 30% glass fiber reinforced mixed PPO/PS |

|

Number of membrane plates |

42 |

|

Membrane spacing |

8mm |

|

Filtration area |

7.5m2 |

|

Maximum negative pressure (suction) pressure |

-0.7bar |

|

Maximum positive (backwash) pressure |

1.2bar |

|

Operating temperature |

5-65℃ |

√ Membrane bioreactor

√ High standardization of drinking water

√ Seawater desalination pretreatment

√ Inorganic particulate solid-liquid separation

√ Powdered activated carbon coupled full-scale double-effect filtration (PFAS removal)

√ Chlor-alkali chemical brine refining

√ Sludge concentration