18072885002

Circulating water systems play a vital role as energy media in metallurgy, petrochemicals, and air conditioning systems. Circulating water systems are prone to excessive hardness due to long-term operation. The accumulation of calcium and magnesium ions forms scale, which clogs pipes, reduces heat exchange efficiency, and accelerates equipment corrosion, leading to increased operational costs and production risks. Efficiently and reliably addressing the challenge of circulating water hardness removal has become a core need for many companies. Today, we'll use a 30 m³/d circulating water hardness removal project at a chemical company as an example to explore how silicon carbide ceramic membrane technology can provide the solution.

01 Project Basic Information

- Treatment Target: Chemical production cooling wastewater (high-hardness water primarily composed of calcium and magnesium ions);

- Core Requirement: Completely separate hardness-causing substances, ensuring the produced water hardness meets standards and can be reused in the cooling system;

- Applied Product: Hard Membrane silicon carbide ceramic flat membrane.

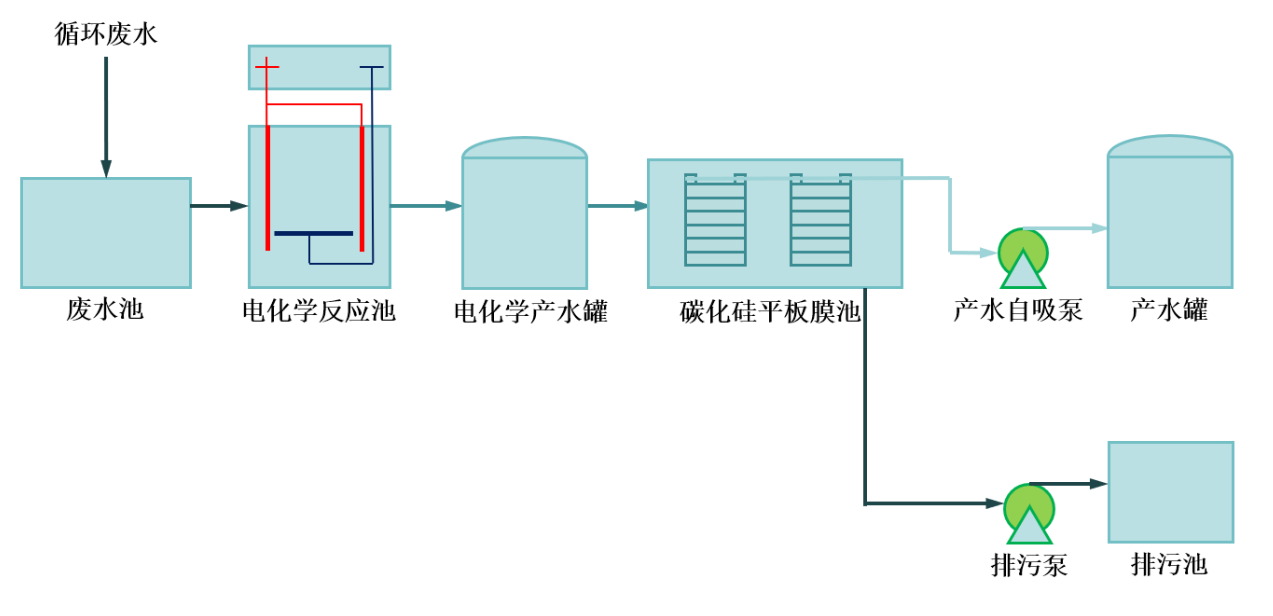

02 Process Description

This project has a designed treatment capacity of 30 m³/d and utilizes an electrochemical softening + silicon carbide flat membrane filtration process. The treated water is either reused in the cooling system or discharged.

In this process, the silicon carbide flat membrane provided by Jianmo Technology plays a key role in "separating hardness and purifying water," providing reliable support for the overall process.

03 Process Advantages Analysis

1.High Separation Precision and Strong Adaptability

The nanoscale pore size of the silicon carbide ceramic flat membrane provides a high retention rate for calcium and magnesium precipitates after electrochemical treatment, ensuring that the produced water hardness remains consistently within standards and meets the requirements for recycled water reuse.

2.Pollution Resistance and Low Operation and Maintenance Costs

Silicon carbide is chemically resistant and highly resistant to contamination, capable of withstanding the complex operating conditions of recycled water. The silicon carbide ceramic membrane boasts a lifespan of up to 20 years, eliminating the need for frequent filter media replacement. The membrane system has a long cleaning cycle, requiring only regular low-pressure chemical cleaning, reducing operation and maintenance costs.

3.Significant Water Savings

The membrane system reuses produced water for backwash, eliminating additional water consumption, effectively increasing the recycled water reuse rate, reducing fresh water purchases and wastewater discharge, and meeting the company's water conservation and emission reduction needs.

4.Automated Operation, Minimizing Manpower

Equipped with a PLC intelligent control system, it can be linked with the electrochemical softening unit to monitor operating parameters in real time and automatically adjust them. No dedicated personnel are required; only regular inspections are required to ensure system stability.

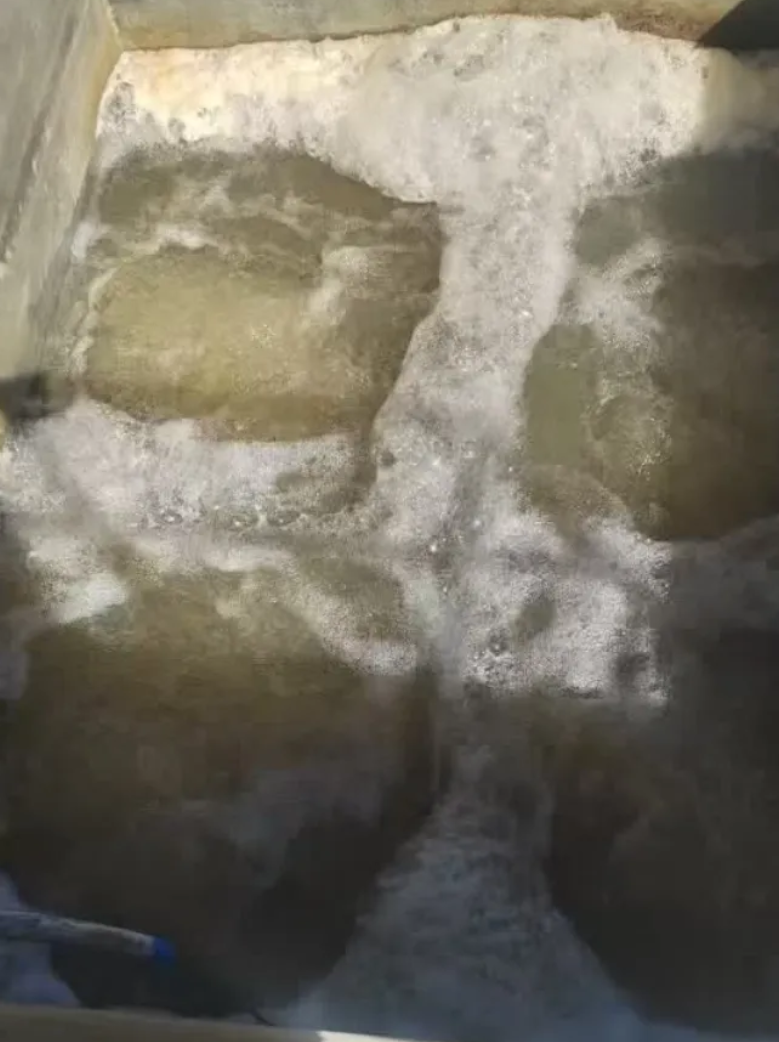

04 On-site photos