18072885002

This is the last chapter of the Mine Water series. Today, we will introduce to you typical cases of JMFILTEC's silicon carbide column membrane, flat sheet membrane, and mine water.

Preface

Silicon carbide flat sheet membrane is made by sintering high-purity silicon carbide powder at high temperature, and is currently the membrane material with the best hydrophilicity and anti pollution ability.

Silicon carbide flat sheet membrane and case introduction

· The membrane surface with high negative charge can ensure excellent pollution resistance across a wide pH range;

· Ideal operating conditions - when the pH of PAC addition is less than 6, the membrane surface can maintain a negative charge of -25~-30 millivolts, making it difficult for soluble organic carbon and transparent outer polymer particles to adhere to the membrane surface;

· It is easy to clean negatively charged substances from the membrane surface in water, such as bacteria, algae, MLSS, transparent outer polymer particles, and oil substances.

Main technical parameters of silicon carbide flat sheet membrane components and membrane modules

| Effective Filtration Area | 0.177m2 |

| Supporting Material | Silicon carbide |

| Filter Layer Material | Silicon carbide |

| Membrane Aperture | 100nm |

| Size Specifications | L600*W145*T6 |

| Operating Temperature | 4~50℃ |

| PH | 2~12 |

| Maximum Operating Pressure | -0.6bar |

| Maximum Backwash Pressure | 1.2bar |

| Cleaning Method | Backwashing/air scrubbing/spraying/chemical cleaning |

| Size L * W * H | 746*66*160nm |

| Weight | 44.8Kg |

| Membrane Shell Material | NORYLTM resin 30% glass fiber reinforced PPE/PS |

| Number of Membranes | 42 |

| Distance between Membranes | 8mm |

| Filtering Area | 7.5m2 |

| Maximum Flow Rate | 9m3/h |

| Maximum Negative (Suction) Pressure | -0.6bar |

| Maximum Positive (Backwash) Pressure | 1.2bar |

| Operating Temperature | 5~45℃ |

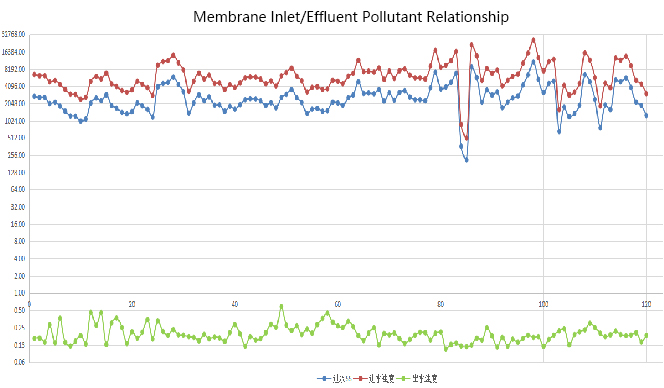

Experimental data

1)Suspended solids concentration

Concentration range:1000~4000mg/l

Average concentration:2335.51mg/l

2)Influent turbidity

Concentration range:2000~8000NTU

Average concentration:6632.82NTU

3)Effluent turbidity

Basically less than 0.5NTU, with an average turbidity of 0.2NTU

Note: The concentration of pollutants in the influent fluctuates greatly, with a maximum concentration of 10850mg/L (turbidity: 26040NTU). The effluent water quality is still good, with a turbidity of 0.168NTU.

Specific cases

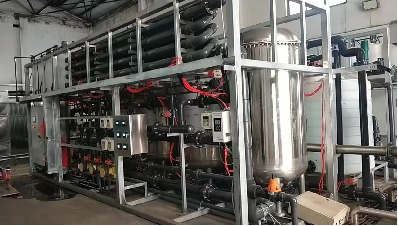

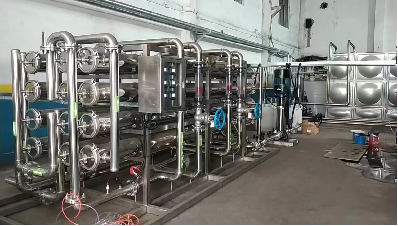

1500 tons/day positive pressure flat sheet membrane&RO system

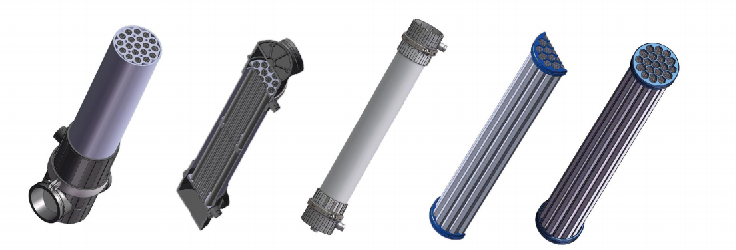

Silicon carbide column membrane and case introduction

This product is an innovative product that breaks the boundary between the application scenarios of inorganic and organic membranes. It combines the advantages of ceramic membrane products being sturdy and durable, as well as high filling density of organic membrane products. The usage method is similar to the height of organic membrane column membranes, which compensates for the high requirements for inlet water quality, high backwash water consumption, and the risk of wire breakage in ultrafiltration membrane technology. It can improve the water yield of ultrafiltration systems and reduce chemical cleaning costs.

The silicon carbide cylindrical ceramic membrane is composed of multiple built-in silicon carbide ceramic filter cartridges spliced together. The unique structural design makes the hydraulic distribution of the water production and backwashing channels of each tubular membrane more uniform, and the backwashing recovery effect is outstanding.

Product features and advantages

★ The core material silicon carbide is a more advanced and ideal ceramic membrane material compared to alumina, with better hydrophilicity, higher porosity, excellent cleaning and recovery ability, and no fear of oil pollution;

★ High mechanical strength, no risk of wire breakage, good wear resistance and impact resistance, stable water quality during long-term operation;

★ Good anti pollution performance, resistant to water fluctuations, and stable long-term operating flux;

★ Good chemical stability, acid and alkali resistance, strong oxidant resistance, high temperature resistance, organic solvent resistance, cleaning resistance, and easy recovery of flux after cleaning;

★ High filtration accuracy (up to 20nm), effectively removing pollutants such as particles, colloids, microorganisms, and organic matter from water;

★ The system has low preprocessing requirements, which reduces the total investment and operating costs of the system;

★ Vertical installation, standardized and modular design, simplifying system pipelines;

★ Competitive investment costs and excellent lifecycle;

★ Compatible with traditional organic membrane ultrafiltration systems;

Specific case

500 tons/hour mine water silicon carbide ceramic core column membrane system

Inflow TLSS = 50~2000ppm

Production water TLSS<1ppm、turbidit<0.2NTU

That's all for the series of mine water treatment content. Thank you for reading. If you have any questions or cooperation intentions, you can leave a message on our website or call 13282817371.