18072885002

Silicon Carbide Tubular Membrane System

Silicon carbide tubular membrane technology falls under the category of ultrafiltration. It is a type of "cross-flow filtration" fluid separation process. The feed liquid flows at high speed within the membrane tube channels. Driven by pressure, the clarified permeate with small molecules permeates outwards perpendicular to the membrane channels, while the turbid concentrate containing large molecules is retained, achieving the clarification, separation, concentration, and purification of the fluid material.

Ultrafiltration cleaning processes are divided into physical cleaning and chemical cleaning. Physical cleaning includes backwashing, which removes deep-seated and surface contaminants from the membrane pores through a reverse water flow (entering from the permeate end of the membrane module and permeating the pores). Chemical cleaning uses chemical agents to remove contaminants such as colloids, organic matter, and inorganic salts that form on and inside the ultrafiltration membrane.

01 Silicon Carbide Ceramic Tubular Membrane System Operation Mode

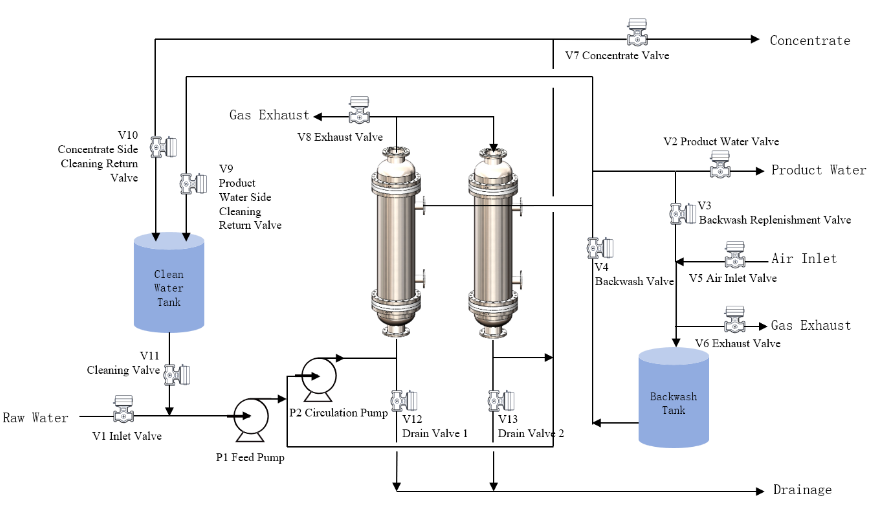

The operation mode of the silicon carbide tubular membrane ultrafiltration system is as follows:

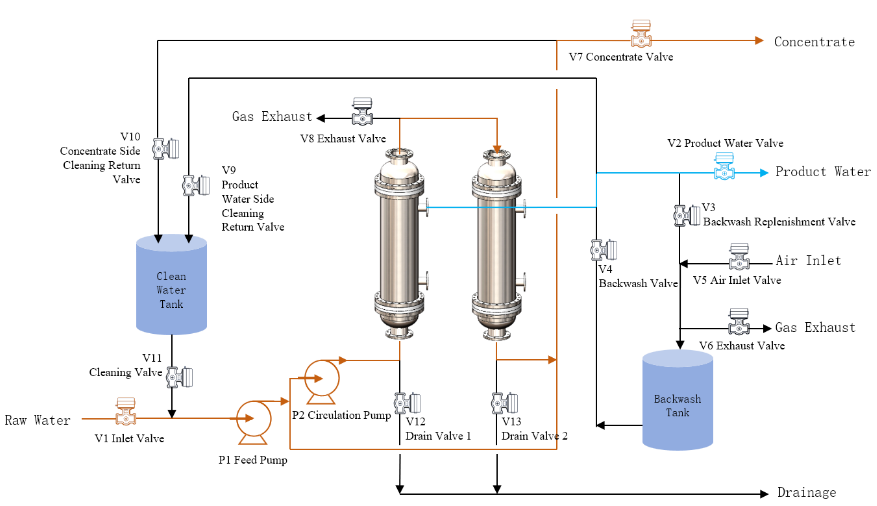

The membrane filtration process includes the following steps:

◆ Permeate: The permeate step removes suspended solids and particulate matter from the water, achieving clarification, separation, concentration, and purification of the fluid material;

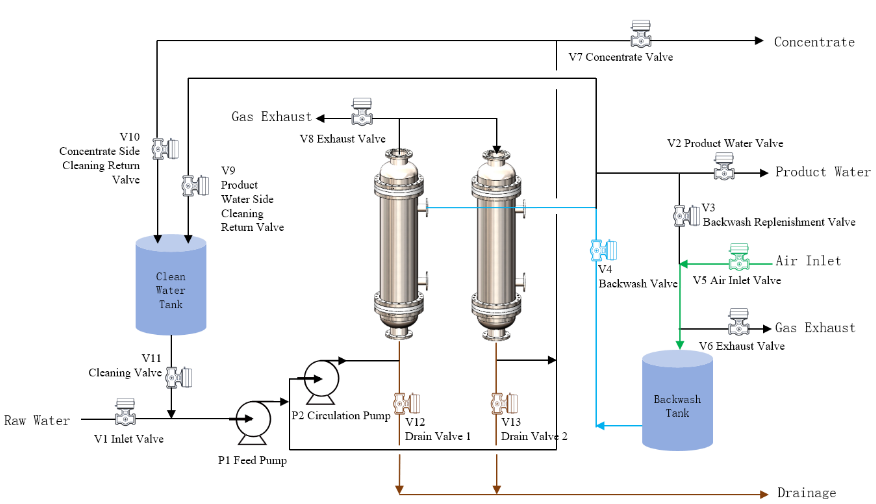

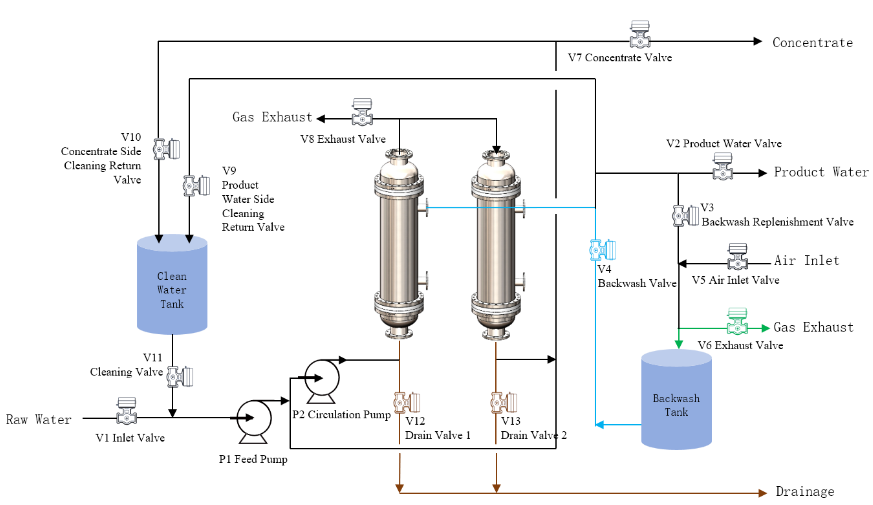

◆ Backwash: Periodic backwashing is required to remove suspended solids from the membrane surface;

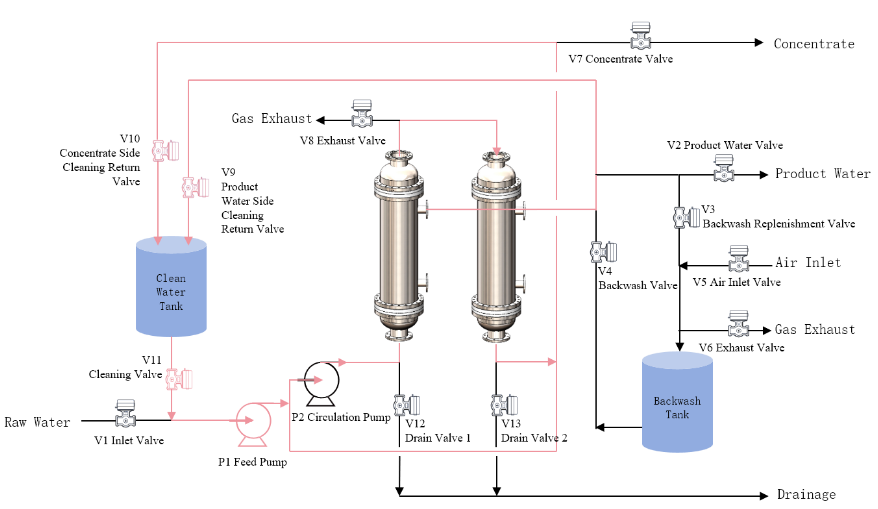

◆ Chemical Cleaning: Chemical agents are used to decompose and destroy pollutants, thoroughly cleaning them.

02 Silicon Carbide Ceramic Tubular Membrane System Operation Process

1.Water Injection & Venting

When the system is running for the first time or when the liquid inside the membrane is emptied, water injection is needed to vent the gas in the system before operation.

2.Backwash Tank Refill

After the water injection and venting steps are completed, the backwash tank is refilled to the set high liquid level to prepare for subsequent backwashing.

3.Permeate Filtration

Cross-flow filtration, driven by pressure, allows the clarified permeate (small molecules) to pass through the membrane filter layer perpendicularly to the membrane channels, while the turbid concentrate containing large molecules is retained.

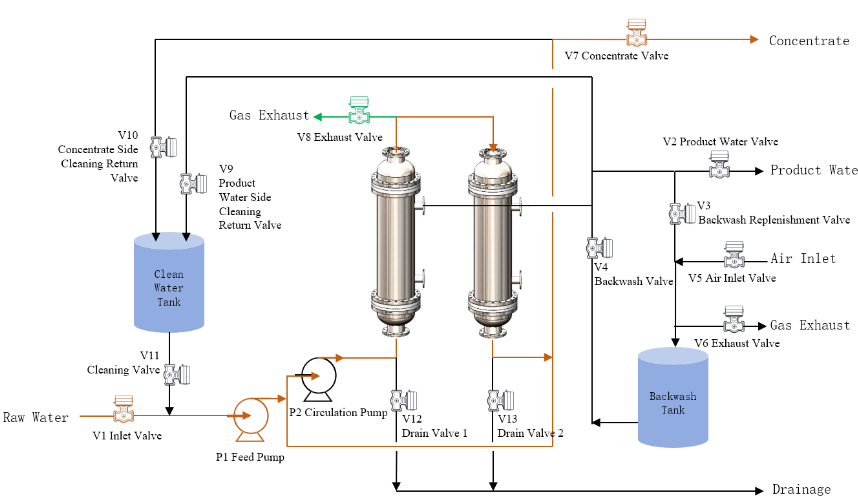

4.Physical Cleaning

During backwashing, clean permeate enters the membrane module from the permeate side, penetrating the ceramic membrane in the reverse direction to flush away contaminants accumulated on the membrane surface, subsequently carrying solid contaminants out of the system.

①Backwashing

②Backwashing Exhaust

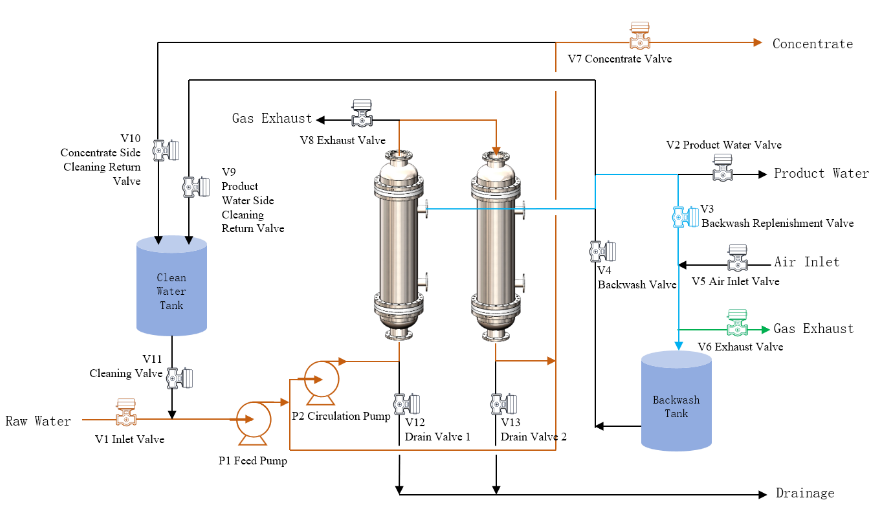

4.Chemical Cleaning

CIP (Clean-In-Place) is a cleaning process that restores the membrane's permeability to a clean state. Its frequency is affected by the feed water quality.

03 Commonly Used Cleaning Agents and Cleaning Water Quality Requirements for Silicon Carbide Ceramic Tubular Membranes

①Commonly Used Cleaning Agents

The following table lists commonly used chemical cleaning agents:

| Agent Type | Commonly Used Agent |

| Oxidizing Agent | Sodium Hypochlorite (NaOCl) |

| Alkaline Agent | Sodium Hydroxide (NaOH) |

| Acidic Agent | Hydrochloric Acid (HCl)/Citrate |

Note: Specific agent dosages can be adjusted according to actual site conditions.

②Cleaning Water Quality Requirements

The cleaning water used to dissolve cleaning chemicals can be UF permeable water, pure water, or other relatively clean water sources. It must meet the following conditions:

| Item | Parameter |

| Total Hardness | <80ppm (carbonate content) |

| Staining Index (SDI) | <3 |

| Total Organic Matter | <8ppm |

| Iron Ions | <0.5ppm |

| Silicon Ions | <5ppm |

Note: The specific cleaning water quality can be adjusted according to the actual site conditions.