18072885002

Application of Silicon Carbide Ceramic Membrane in Membrane Chemical Reactors

Zhejiang Jianmo Technology Co., Ltd

Membrane Coagulation Reactor (MCR) is a technology that combines chemical treatment processes with membrane separation processes, mainly used for removing suspended solids, heavy metals, hardness, turbidity, and silicon. Membrane chemical reactors can even be combined with processes such as membrane concentration and evaporation crystallization to achieve reduction and near zero discharge of concentrated brine, providing a new technological route and solution for the resource utilization and reuse of concentrated brine.

CASE SHOWS

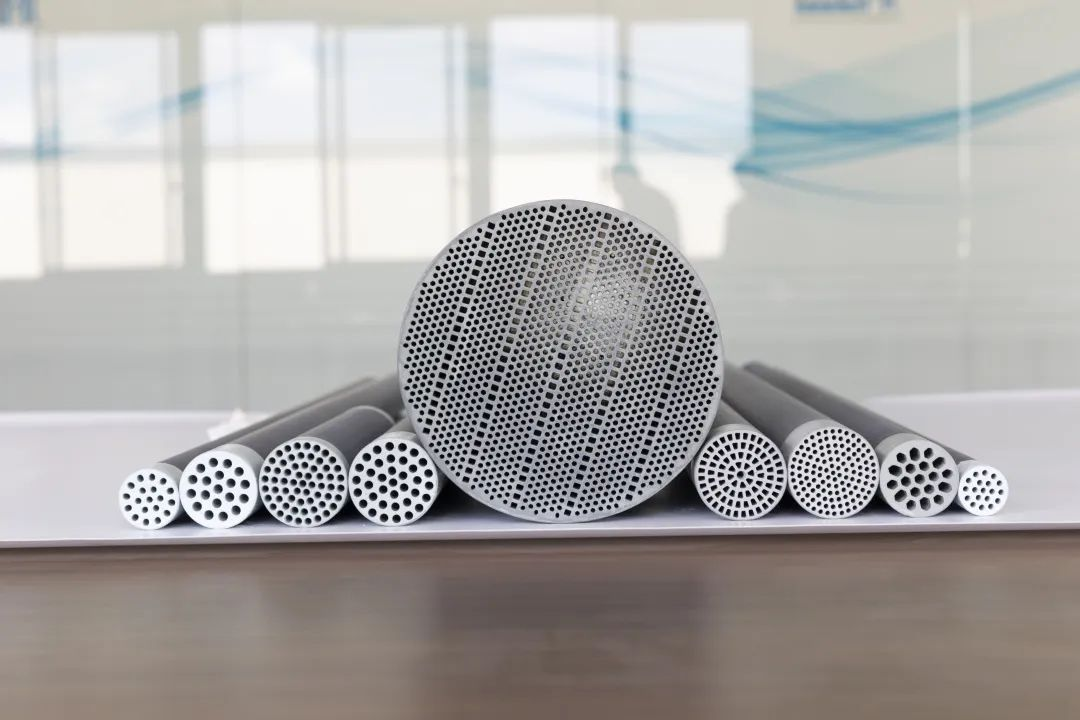

Definition and characteristics of silicon carbide membrane

Definition of silicon carbide membrane

It is a high-precision microfiltration and ultrafiltration grade membrane separation product made of high-purity silicon carbide fine powder through recrystallization sintering technology, which has high throughput, corrosion resistance, easy cleaning, and long service life. Currently, the highest filtration accuracy can reach 20 nanometers.

The characteristics of silicon carbide membrane

1.High throughput, pure water flux ≥ 3000LMH@25 ℃

2.Corrosion resistance

3.Easy to clean

4.Excellent oil-water separation performance

5.The service life of silicon carbide membrane products can reach more than 10 years.

Case One

CASE SHOWS

After chemical precipitation of wastewater containing heavy metals in the electroplating industry

Scale of solid-liquid separation project: 6 × 100 tons/day · set

Case Introduction

The design style of this project is inspired by the integrated system of POREX. UPVC membrane shells are filled with 7 pcs of φ 40 silicon carbide membrane components inside, with a design flux of up to 220LMH for this project.

Case 2

CASE SHOWS

The scale of the chemical precipitation and solid-liquid separation project for heavy metal wastewater in the electroplating and electroplating industry has a processing capacity of 100 tons/day · set

Case Three

CASE SHOWS

Softening of flat sheet membrane

Project scale 2 x 50 tons/day · set

Design flux 260LMH

Case Four

CASE SHOWS

Replace the alumina ceramic membrane

Chlorine alkali chemical brine refining

Project scale and processing capacity of 240m ³/ h · set

915 pieces φ 31-3.8-19-1200

Design flux 1000LMH

Case 5

CASE SHOWS

Garbage Transfer Station · Kitchen Waste Treatment Project Scale: 20 tons/day · set

Project implementation in progress

Process route:

Air flotation → pH regulation tank → electrocoagulation tank → sedimentation tank → silicon carbide flat sheet membrane → electrocatalytic oxidation → standard discharge

The typical application scenarios of membrane chemical reactors currently include:

1、Chlorine alkali chemical brine refining, combined with dual alkali method to remove calcium and magnesium ions;

2、Softening of landfill leachate membrane as RO pretreatment;

3、Softening of RO concentrated water membrane in high salinity mine water membrane concentration+evaporation process;

4、Softening of desulfurization wastewater membrane in thermal power plants;

5、The wastewater containing heavy metals in the electroplating industry is reused as RO pretreatment.

The above case sharing is just a starting point, and in the future, there will only be more and more projects applying silicon carbide membranes to membrane chemical reactors.