18072885002

Application of Silicon Carbide Membrane in High Standard Tap Water Purification

--Zhejiang Jianmo Technology Co., Ltd--

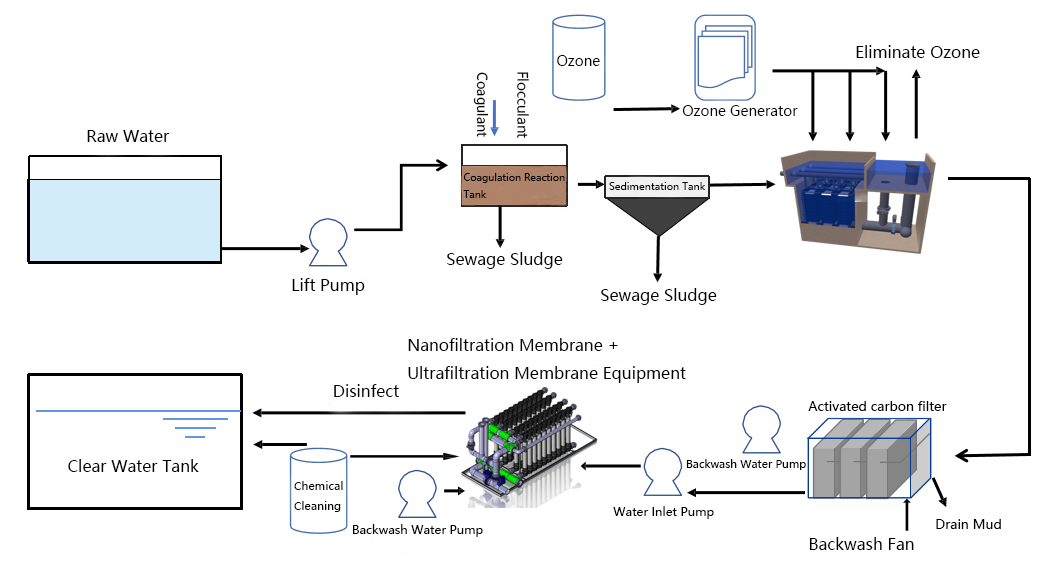

In last week's article, we shared the application of silicon carbide ceramic membranes in membrane chemical reactors. In this article, we will share the application scenarios of silicon carbide flat sheet membranes in high standard tap water purification.

With the breakthrough of filtration technology and the increasing demand for high-quality drinking water, the scale and quantity of domestic water plants using ultrafiltration technology and dual membrane (ultrafiltration+nanofiltration) technology are increasing year by year.

Silicon carbide membrane

--SIC--

Silicon carbide membrane is a high-precision microfiltration and ultrafiltration grade membrane separation product made from high-purity silicon carbide fine powder through recrystallization sintering technology, which has high throughput, corrosion resistance, easy cleaning, and long service life. Currently, the highest filtration accuracy can reach 20 nanometers.

The characteristics of silicon carbide membrane:

High throughput, pure water flux ≥ 3000LMH@25 ℃

Easy to clean, efficient in cleaning (saves chemicals and reduces the amount of cleaning wastewater generated)

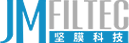

Equipment parameters of silicon carbide flat sheet membrane

--SIC--

Membrane element parameter

| Membrane Material | Silicon Carbide |

| Sealing Material | Viton/EPDM/NBR |

| Water Collector Material | Glass fiber reinforced PPS plastic |

| Effective Filtration Area of Single Membrane Element | 0.177m2 |

| Filtration Accuracy | 0.1um |

| Pure Water Flux | 5000LMHbar@20℃ |

Membrane component parameter

| Membrane Module Material | Glass Fiber Reinforced PPS Plastic |

| Sealing Material | Viton/EPDM/NBR |

| Membrane Spacing (Adjustable) | 8 mm |

| Maximum Membrane Filling Area | 7.5 m2 (42 membrane elements) |

| Maximum Water Production Capacity | 7.5 m3/hr |

| Maximum Working Pressure | -0.7 bar |

| Maximum Backwash Pressure | 1.2 bar |

| Operating Temperature | 1~45℃ |

| pH | 1~14 |

Case shows

--CASE SHOWS--

At present, for the purification of tap water, we adopt the third-generation short process silicon carbide ultrafiltration pretreatment+hollow fiber membrane filtration technology.

The silicon carbide ceramic flat plate ultrafiltration system can integrate the sand filter, ozone contact oxidation tank, and ultrafiltration system into one, greatly saving land area and shortening the process flow. It has a more flexible process design, such as a dynamic dual effect filtration process combined with powder activated carbon.

Case One

28800 tons/day salmon aquaculture water pretreatment project

Process route: seawater → baffled reaction tank (two-stage reaction, sodium hypochlorite and flocculant) → silicon carbide flat sheet ultrafiltration system → seawater desalination reverse osmosis, stable operating flux of 220LMH.

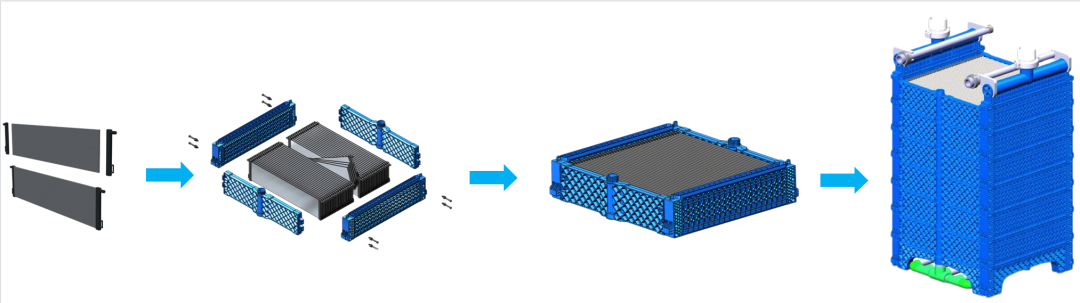

Case 2

5000 tons/day drinking water project

Process route: flocculation sedimentation tank → silicon carbide ceramic core column membrane → disinfection → production water tank.

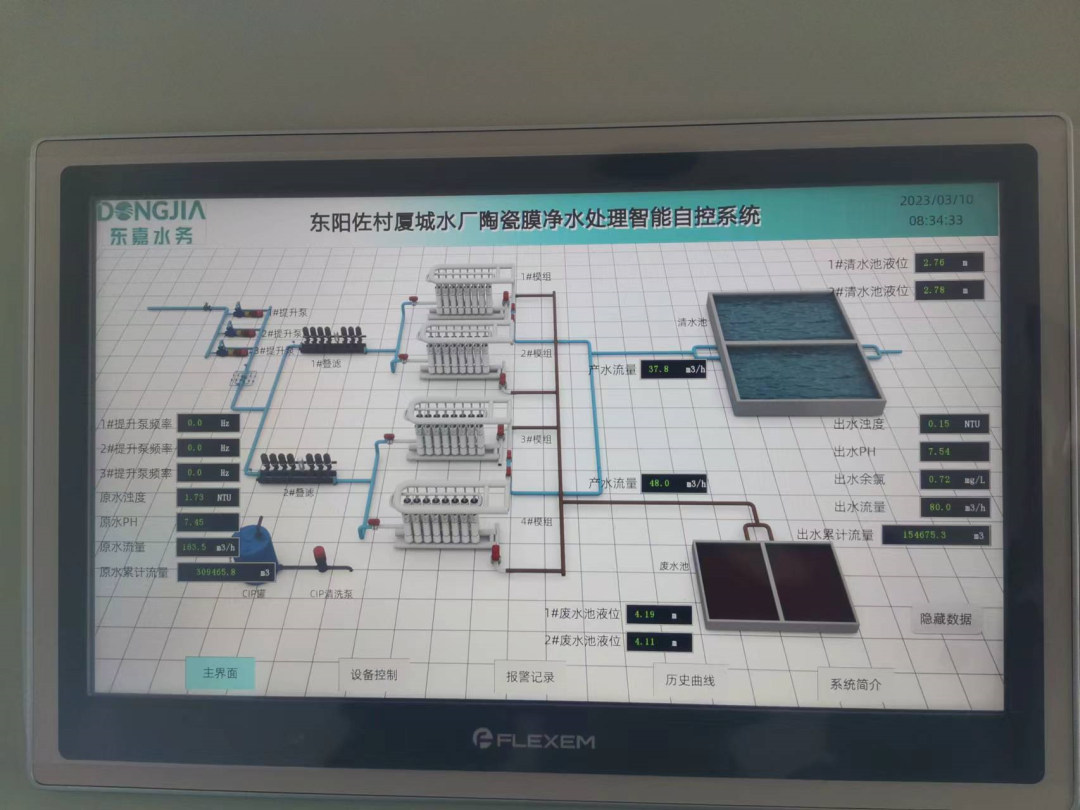

Case Three

50 tons/day Dancun Water Plant Project

Process route: flocculation sedimentation tank → silicon carbide ceramic core column membrane → disinfection → production water tank.