18072885002

"Application of silicon carbide membrane brine refining"

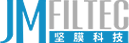

Silicon carbide materials have natural porosity, excellent chemical stability, excellent thermal conductivity and thermal stability, making them an ideal choice for producing special membrane materials. It is a typical "three resistant material" that is resistant to corrosion, high temperature, and impact. Due to its lack of melting point, it has a natural tendency towards porous materials, which can bring higher filtration flux and lower pressure drop.

The silicon carbide membrane independently developed and produced by JMFILTEC is a high-tech cutting-edge new material, with mastery of core technology and independent intellectual property rights, breaking through international monopolies. Silicon carbide ceramic flat sheet membrane, as a new material, has been included in the Key Product Catalogue of Strategic Emerging Industries in the 13th Five Year Plan of the country!

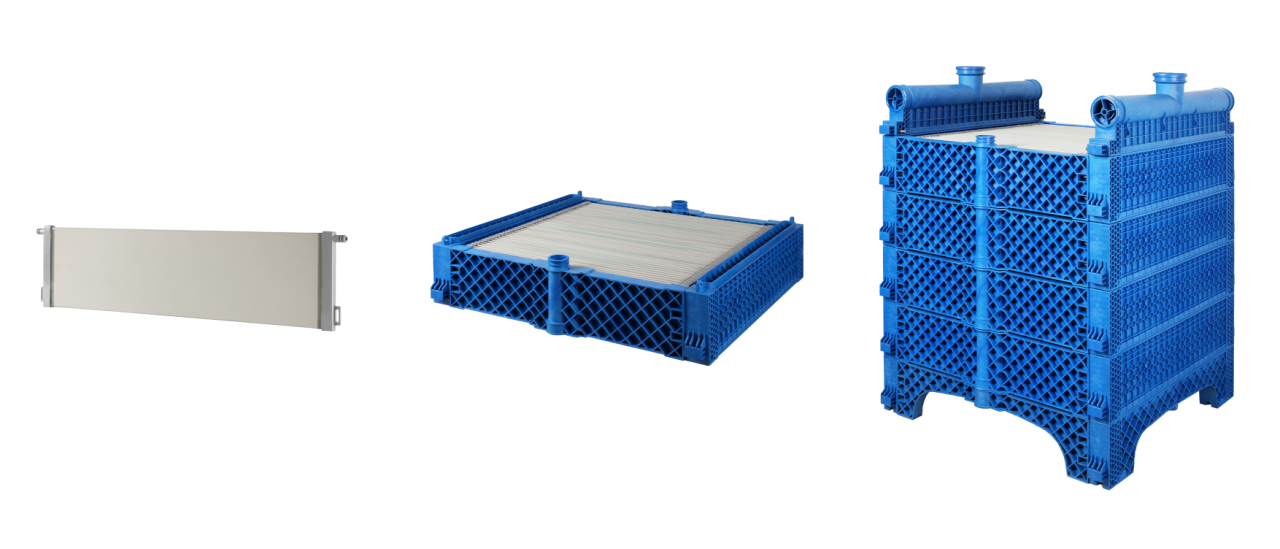

The silicon carbide ceramic membrane brine refining technology is a mature process that utilizes the strong anti-pollution, acid and alkali resistance, and strong mechanical erosion resistance characteristics of silicon carbide ceramic membrane materials. It also adopts an efficient "cross flow" filtration method, which can provide stable and reliable high-quality brine for a long time. It has advantages and effects that other refining and filtration technologies cannot achieve. The crude brine is subjected to salt transformation, refining reaction, crude filtration, and tubular membrane filtration to obtain refined brine that meets the primary brine product specifications.

1、 Narrow pore size distribution of membrane elements, cross flow filtration, and high separation accuracy;

2、Acid and alkali resistance, solvent resistance, oxidation resistance, and high temperature resistance;

3、High mechanical strength, good wear resistance and erosion resistance;

4、Good thermal stability and stable material properties;

5、High permeability, long service life, and strong regeneration ability;

6、Strong resistance to microbial degradation and erosion, as well as pollution;

7、Short process flow, small equipment footprint, and more cost-effective investment;

8、The application of titanium components and the application of all titanium coarse filters;

9、The solid content of the discharged concentrated liquid is stable;

10、 Fully automated process design;

11、Fully enclosed operation process;

12、Energy saving and consumption reduction, with low operating costs.

Comparison of brine refining processes between silicon carbide membrane and organic membrane

| Organic Membrane | Silicon Carbide Membrane | |

| Process Flow | long | Short |

| Require Preprocessor | Yes | No |

| Salt Adaptability | Low | High |

| Membrane Pore Size/nm | 200 | 40 |

| Filtering Method | Dead end filtration | Cross flow filtration |

| SS Index of Produced Water | Good | Excellent |

| Calcium and Magnesium Index of Produced Water | Good | Excellent |

| Equipment Material | Steel lining rubber | Titanium |

| Operating Pressure/Mpa | <0.15 | 0.25-0.35 |

| Membrane Component Lifespan/year | 3-4 | 5-8 |

| Land Occupation Area | Large | Small |

| Investment Cost | High | Low |

Comparison of brine refining processes between silicon carbide membrane and traditional inorganic membrane

| Material | Al2 O3 + ZrO2 | SiC |

| Pore Size | 50nm | 40nm |

| Membrane Channel | 3.8mm | 4.2mm |

| Testing Flux with Pure Water | 600L/m2·h | 1000L/m2·h |

| Acid and Alkali Resistance, Wear Resistance | Good | Excellent |

| Membrane Service Life | 5 years | 8 years |

| Electricity Consumption Per Ton of Water Production | High | Low |

| Membrane Replacement Cost | High | Low |

| Land Occupation Area | Large | Small |

| Investment Cost | High | Low |

Why is silicon carbide membrane called the future filtration technology?

1.Ultra high throughput——The flux is 3-6 times that of ceramic membranes; Organic membranes are 5-30 times smaller in footprint, lower in operating costs, and require less investment in supporting facilities.

2.Safer materia ——Silicon carbide crystal ceramics are sintered at ultra-high temperatures, with a single component, no residue, and no heavy metals, ensuring pharmaceutical grade safety.

3.Better filtration efficiency——The filtration accuracy covers microfiltration, ultrafiltration, and nanofiltration, meeting various water quality purification needs.

4.Ultra long service life——Can be used for more than 5 years in strong acid, strong alkali, and high temperature environments; Ordinary water purification can be used for more than 20 years.