18072885002

With increasingly stringent environmental protection requirements, the demand for efficient, stable, and long-lasting treatment technologies in the wastewater treatment field is becoming increasingly urgent. Even after biochemical treatment, domestic wastewater still retains small amounts of suspended solids, colloids, microorganisms, and other pollutants. Traditional treatment processes, such as sand filtration, suffer from weak anti-fouling capabilities, complex operation and maintenance processes, and insufficient stability in achieving treatment standards. This article, based on a practical engineering case study, illustrates the efficient application of silicon carbide ceramic membrane technology in the deep treatment stage of wastewater treatment plants, providing a practical technical solution.

01 Project Basic Information

|

Wastewater Type |

Domestic Wastewater |

|

Application Product |

JMFILTEC - Silicon Carbide Flat Sheet Membrane |

|

Application Type |

Deep Treatment |

|

Treatment Requirements |

Achieve stable water quality compliance for discharge |

02 Project Background

Due to local development, the existing wastewater treatment plant could not meet the actual needs. Therefore, an expansion project was implemented at a different site. The newly constructed wastewater treatment plant will meet the needs of domestic wastewater treatment and related environmental protection requirements.

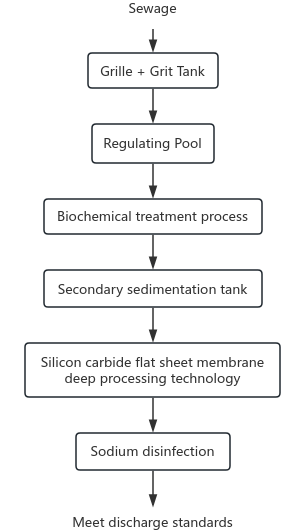

03 Process Flow Description

The project adopts a process route of "pretreatment + biochemical reaction + silicon carbide flat sheet membrane deep treatment + disinfection":

◆ Pretreatment: Removes large particulate suspended solids and impurities from the raw water, stabilizing water quality;

◆ Biochemical reaction: Decomposes organic matter, nitrogen, phosphorus, and other pollutants in the water through biochemical processes, reducing water quality load;

◆ Deep treatment: The silicon carbide flat sheet membrane serves as the core unit, precisely trapping remaining suspended solids, colloids, and microorganisms with its nanoscale pore size, ensuring stable and compliant effluent quality;

◆ Disinfection treatment: Kills pathogenic microorganisms through disinfection processes, ultimately ensuring compliant effluent discharge.

Process Advantages Analysis

1.High Separation Precision and Excellent Effluent Quality: The nano-sized pore design ensures high retention rates of suspended solids and microorganisms, guaranteeing stable compliance with standards for turbidity, TSS, and other indicators in the effluent.

2.Strong Anti-fouling and Convenient Maintenance: Made of pure silicon carbide, it is highly hydrophilic and resistant to acid and alkali corrosion. It can withstand the complex water quality of biochemical effluent and is unaffected by fluctuations in the effluent quality, eliminating the need for frequent adjustments to process parameters and simplifying operation.

3.Streamlined Process and Reduced Footprint: Eliminating the traditional multi-stage filtration process shortens the process flow and reduces the floor space required.

4.Long-lasting and Durable with High Cost-Effectiveness: The silicon carbide ceramic membrane boasts high mechanical strength, strong corrosion resistance, and a long service life. It can operate stably for extended periods, exhibiting strong anti-fouling performance, requiring less frequent cleaning, and offering significant advantages in total lifecycle cost.

On-site Photos