18072885002

JMFILTEC Silicon Carbide Ceramic Membrane Selection Guide

Introduction

Silicon carbide ceramic membranes, with their core advantages of high flux, acid and alkali resistance, fouling resistance, and long lifespan, have been widely used in water treatment, material separation, new energy, and other fields. To help customers accurately match their operating conditions, this guide is formulated to clarify the selection principles and suitable scenarios for different membrane modules (tubular, column, and flat sheet), providing a scientific reference for practical applications.

I. Tubular Membrane Selection Principles

Selection based on the solid content in the feed solution: For solid content within 0.5-1%, tubular membranes can be selected. The specific model should be determined by referring to successful case studies of ceramic tubular membranes.

Applicable Scenarios:

·Liquid Hazardous Waste: Reuse of machining cutting fluids, glass cutting fluids, ultrasonic cleaning fluids, and rinsing solutions;

·Chemical Industry: Purification and recovery of strong acids and alkalis, brine refining in chlor-alkali chemical industries, and separation in petrochemical industries;

·Wastewater Treatment: Treatment and zero discharge of oily wastewater, chemical wastewater, papermaking wastewater, printing and dyeing wastewater, electroplating wastewater, desulfurization wastewater from the power and steel industries, heavy metal and rare metal recovery, oil-water separation from kitchen waste, biogas slurry purification, decolorizing agent recovery, and extractant recycling;

·Material Concentration and Purification: Clarification, purification, separation, and concentration of food fermentation liquids, (sulfur-free) sucrose, starch, protein, red wine and health wine, fruit juice, food additives, sweeteners, natural pigment extraction, deep processing of tea, and condiments (such as soy sauce and vinegar) in the food industry.

II. Column Membrane Selection Principles

The selection of column membrane models should be based on successful case studies of ceramic column membranes.

Applicable Scenarios:

·Drinking Water: Suitable for drinking water plants with large treatment volumes and relatively clean water quality. Column membrane modules with large single-membrane area, high packing density, and small flow channels are selected, resulting in compact equipment and a small footprint.

·New Energy: Applications requiring high flux, acid and alkali resistance, long lifespan, low energy consumption, and high recovery rate.

·Wastewater Reuse: Suitable for applications requiring high flux, strong pollution resistance, oxidation resistance, and good resilience.

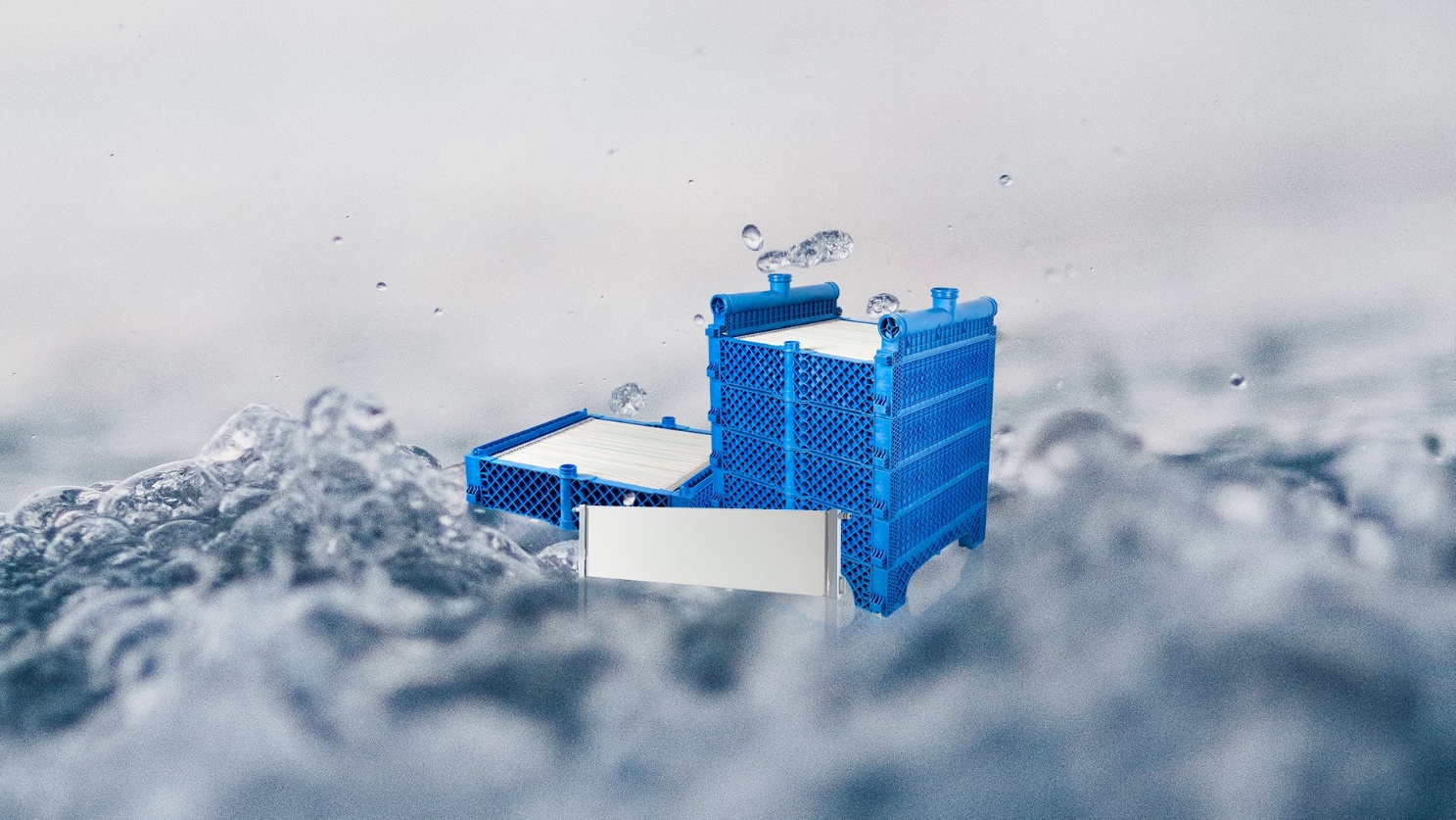

III. Flat Sheet Membrane Selection Principles

Selection should be based on the solid content of the feed solution: For solid content below 1%, flat sheet membranes can be selected. The specific model should be determined by referring to successful case studies of ceramic flat sheet membranes.

Applicable Scenarios:

·Wastewater Treatment: MBR process, domestic sewage, municipal wastewater treatment;

·Drinking Water: Suitable for single-village drinking water projects with small treatment volumes, employing a membrane module stacking design, small footprint, and low energy consumption;

·Seawater Desalination: Seawater desalination pretreatment, short process, small footprint, and low energy consumption;

·Sludge Thickening: Municipal sludge thickening treatment;

·Brine Purification: In the dual-alkali process, purified brine removes impurities.