18072885002

High standard drinking water+

Reform of processing technology

The new version of the national standard "Hygienic Standards for Drinking Water" GB5749-2022 was released in March 2022. Starting from April 1, 2023, urban water supply will fully comply with the "Hygienic Standards for Drinking Water" (GB 5749-2022). Compared with the 2006 version of the standard, the new standard has adjusted the water quality indicators from 106 to 97, added 4 new indicators, and deleted 13 indicators. At present, for the general public, drinking water not only needs to be safe, but also needs to meet the public's acceptability, such as the appearance and taste of the water. The main indicators that affect the appearance and taste of drinking water include hardness, iron, manganese, copper, zinc, chloride, sulfate, etc. In the new standard, these acceptability indicators are mandatory management requirements, and among the four newly added indicators, two of them belong to sensory trait indicators, which are conducive to further improving the taste of drinking water.

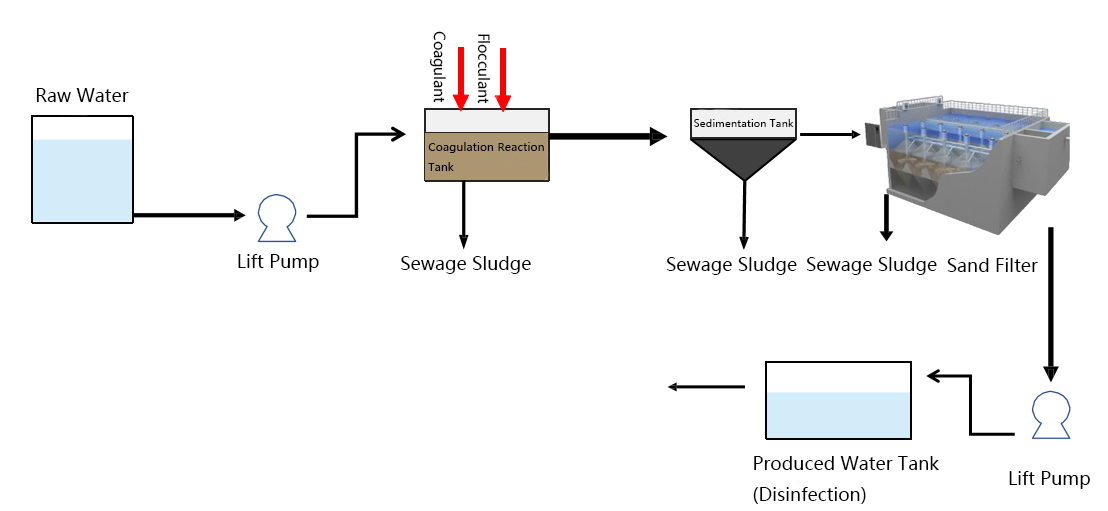

First generation conventional processing technology

01

The first generation conventional treatment process is based on the technology used in the "Hygienic Standards for Drinking Water" GB5749-2006, mainly using sand filters. This treatment process has certain shortcomings in use:

1. 不 Unable to effectively remove ammonia nitrogen and organic pollutants, especially dissolved organic matter.

2. Unable to effectively remove algae and toxins, odors, odors, and endocrine disruptors.

3. Chlorination generates by-products, increasing the variability of the produced water quality.

4. There is instability in the factory water quality and secondary pollution in the pipeline network.

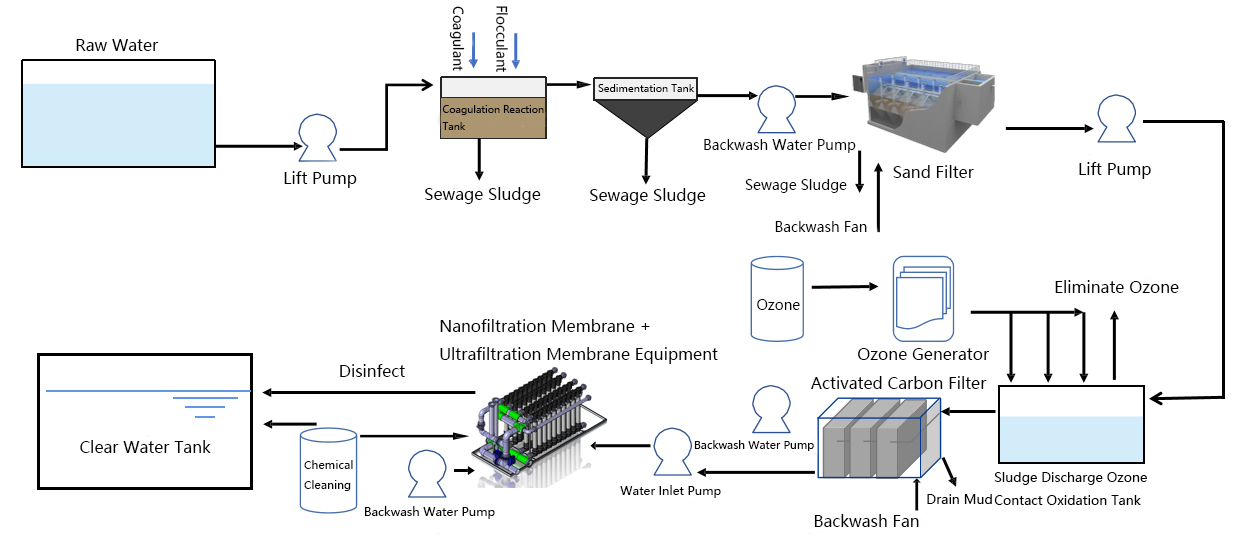

Second generation conventional+deep treatment process

02

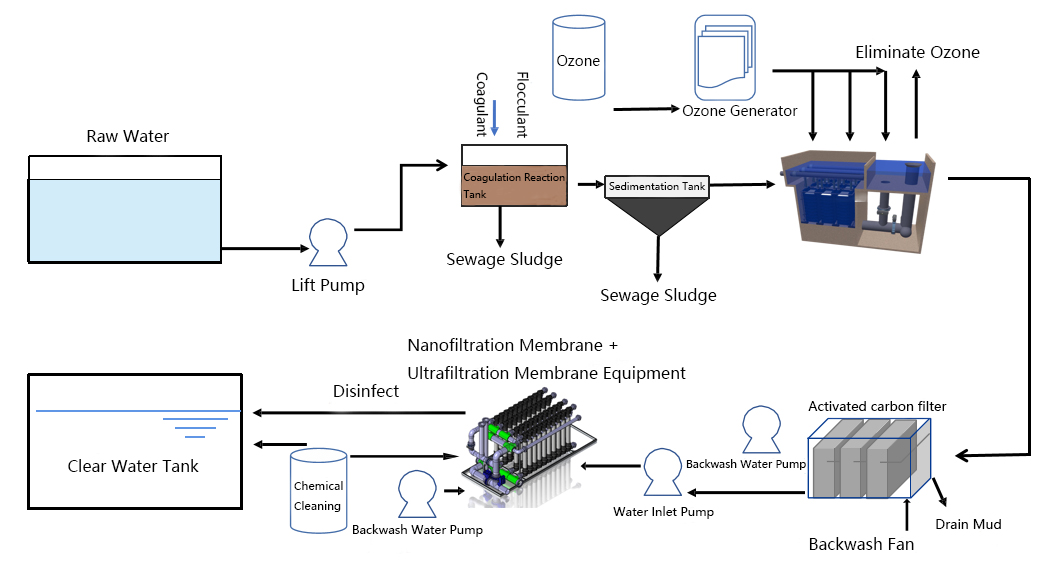

The second generation conventional+advanced treatment process is an upgraded process after the release of the new national standard GB5749-2022 "Hygienic Standards for Drinking Water". After the sand filter, nanofiltration and ultrafiltration membrane equipment have been added, and the effluent water quality meets the new national standard hygiene standard.

Short process silicon carbide ultrafiltration pretreatment+hollow fiber nanofiltration membrane treatment process

03

The third generation is our company's improved short process silicon carbide ultrafiltration pretreatment+hollow fiber nanofiltration membrane treatment process based on the new national standard GB5749-2022 for drinking water hygiene. The silicon carbide ceramic flat sheet ultrafiltration system can integrate the sand filter, ozone contact oxidation tank, and ultrafiltration system into one, greatly saving land area and shortening the process flow. It has a more flexible process design, such as a dynamic dual effect filtration process combined with powder activated carbon. Our silicon carbide ceramic flat sheet ultrafiltration system has its own siphon water production capacity and does not require the installation of a water production self suction pump.

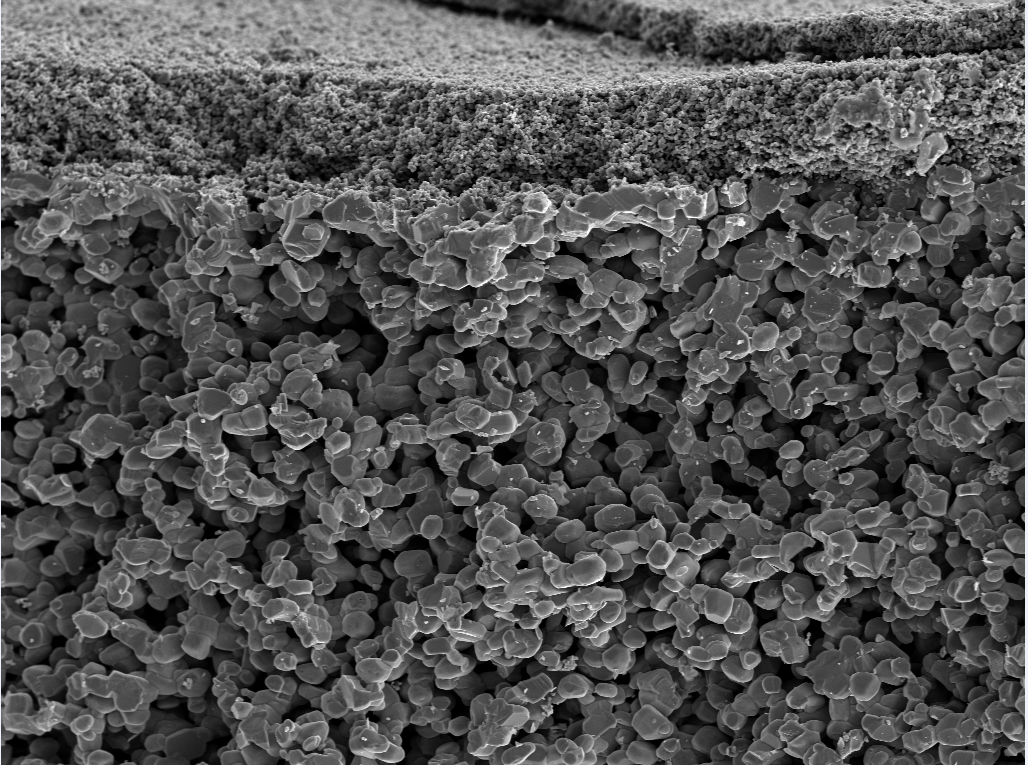

Silicon carbide ceramic membrane

04

Silicon carbide membrane is a high-precision microfiltration and ultrafiltration grade membrane separation product made from high-purity silicon carbide fine powder through recrystallization sintering technology, which has high throughput, corrosion resistance, easy cleaning, and long service life. Currently, the highest filtration accuracy can reach 20 nanometers.

Characteristics of silicon carbide membrane:

High throughput, pure water flux ≥ 3000LMH@25 ℃

Efficient cleaning (saving chemicals and reducing the amount of cleaning wastewater).

Empowering industries with technology

Leading development through innovation

In the future, I come!