18072885002

Scaling and corrosion have been affecting the cooling system. Due to the increasingly serious environmental problems, it is becoming increasingly difficult to prove the legitimacy of using chemical reagents to prevent these problems.

1.Introduction

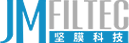

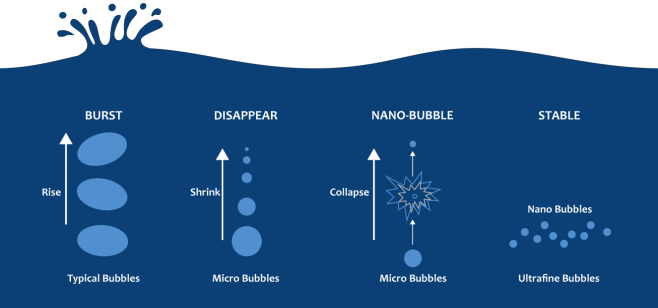

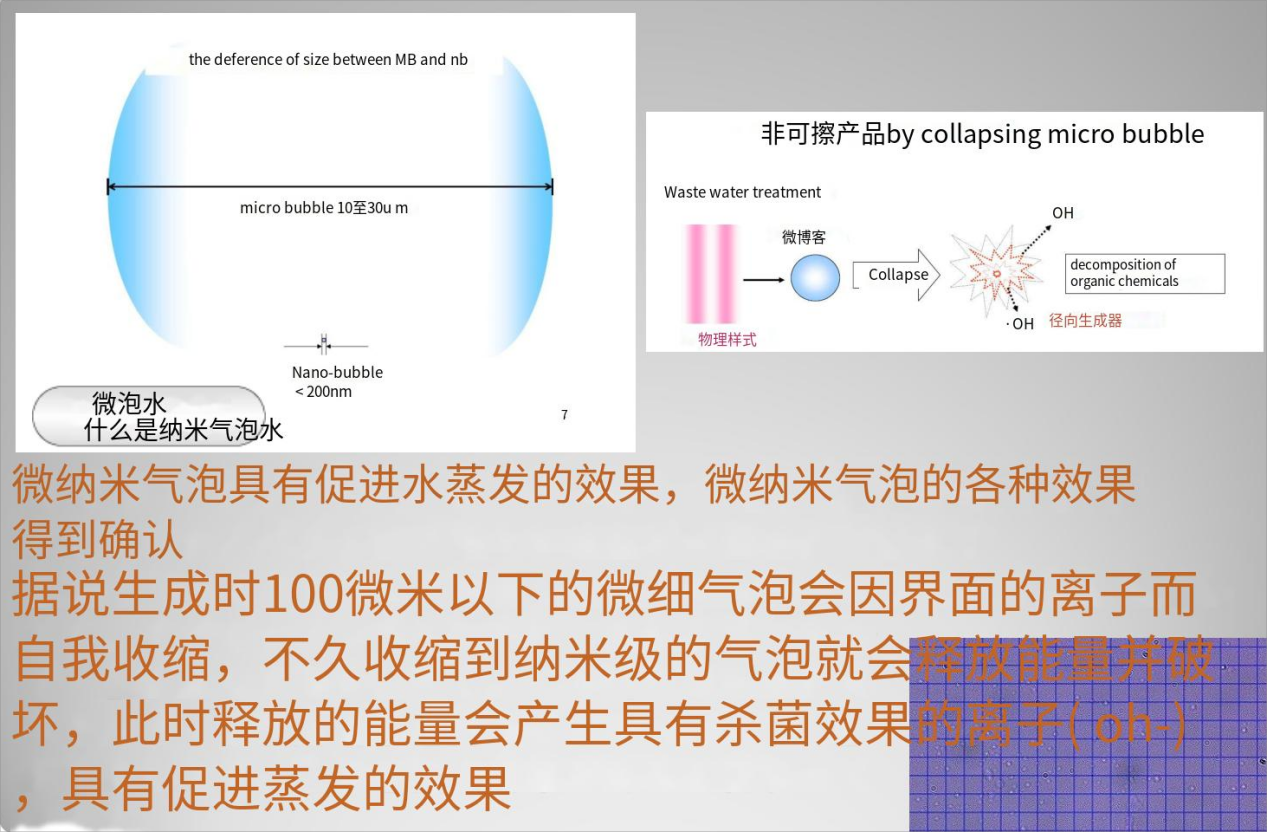

Nanobubbles have been used in many engineering, environmental, biological, and medical applications, and many beneficial results have been reported. Although these benefits sometimes exceed the scientific reasoning behind the occurrence of nanobubbles. Particles and bubbles smaller than 1 micron are nanobubbles. Nanobubbles can be measured using similar methods, such as dynamic light scattering; The gas in the nanobubbles is concentrated and in a high-pressure state, and the gas is transferred to the surrounding liquid until the liquid is saturated with the gas and loses the concentration gradient or the internal pressure of the nanobubbles is balanced with the fluid pressure. These gases alter the chemical environment of the surrounding fluid.

2.Physical and chemical properties of nanobubbles

a. Long residence time in water

b.Good stability in water

c.Can act as a corrosion inhibitor and as a protective coating

Nanobubbles can strongly affect the flow of fluids along micro rough but hydrophobic surfaces. The lifespan of nanobubbles attached to the surface can be several hours, days, and months, and can withstand temperatures close to boiling. In addition, with the help of "pinning", nanobubbles can stay on rough surfaces for a longer period of time. Once some nano bubbles appear on the steel surface, the friction force on the steel surface may decrease. The slip length will increase with the increase of surface coverage, and the contact angle of nanobubbles on rough surfaces will decrease. Due to the erosion/corrosion of steel, the wall friction will decrease and the wettability of rough steel surfaces will be enhanced. After continuous injection of nanobubbles, the slip length further increases when the nanobubbles cover a larger part of the steel surface. Therefore, surface nanobubbles act as coating materials on the steel surface, bringing the following effects

(1)Inhibiting corrosion by increasing slip length

(2)By acting as bubbles, it prevents the active interface from being exposed to acidic thermal fluids

d.Helps to form silica precipitation

Silicon dioxide, which is commonly present in cooling water, can be precipitated by nanobubbles, which are very dense and help suppress metal corrosion in acidic fluids.

The precipitation of amorphous silica is common in power plants, where the fluid is rapidly cooled during the production process. This silica scaling problem is equally important as metal corrosion. At moderate temperatures in power plants, low-carbon steel tends to scale and corrode. In addition, some studies have also found that once an initial amorphous silica precipitation layer is formed, it may hinder further reaction between the steel surface below and the hot fluid. Therefore, silica precipitates can indeed play a role in inhibiting corrosion in acidic medium temperature hot fluids.

Considering a certain corrosion allowance and a 20-year service life, the acceptable corrosion rate of the material is usually considered to be less than 0.1 millimeters per year. However, corrosion is very severe in acidic hot fluid environments, ranging from a few millimeters per year in moderate fluid environments to over 100 millimeters per year in high temperature and high fluid velocity environments. Therefore, pH regulation is one of the most commonly used methods to suppress this strong corrosion, but it can also easily change the chemical properties of the fluid, potentially producing unwanted products. In contrast, we found that nanobubbles, as a chemically benign, environmentally friendly, easy to use, and low-cost additive, have good corrosion inhibition effects, possibly achieved by acting as gas coatings and promoting slight precipitation of silica on steel.

e.It has the function of sterilization and cleaning

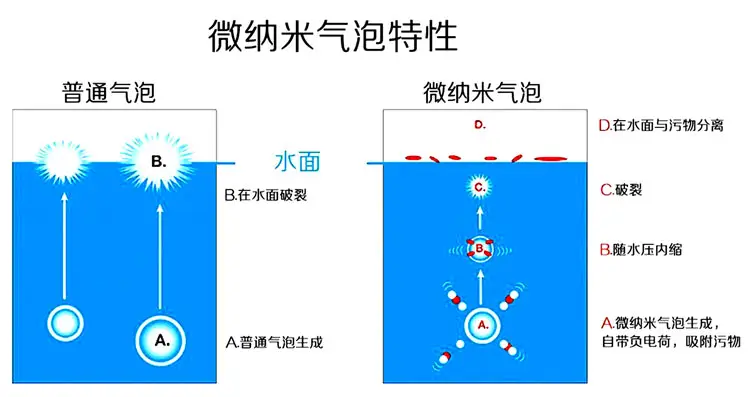

Nanobubbles carry negative charges and aggregate positive (+) substances. Small bubbles have various functions, such as oil removal, detachment of sediment between entering and cleaning objects, and the force and shock wave when bubbles rupture.

One of the major benefits of nanobubbles is their high cleaning power. The cleaning mechanism is considered as follows:

When cleaning the pollutants attached to the surface of silicon wafers, the force and shock wave when the bubbles burst greatly enhance the cleaning force when using ultrapure water jet containing UFB (ultra-fine bubbles/nanobubbles).

Nanobubbles penetrate into oil and penetrate between the boundaries of the adhesive surface, exhibiting a degreasing effect of separation and oil removal. In addition, it can penetrate into narrow spaces between objects in close contact with each other. When nanoscale bubbles merge into microbubbles, microbubbles can act as wedges to separate them. These characteristics enhance the cleaning power. Currently used for cleaning household bathrooms/showers, dishes, and machine parts. It also has a high bactericidal effect. Not only bacteria attached to the surface, but small bubbles can also penetrate the shrimp's body and sterilize it. With tap water and the atmosphere, nearly 90% of bacteria have been successfully sterilized by small bubbles.

Cleaning Comparison Experiment (Pure Water vs. Nano Bubble Pure Water): Results of Cleaning Silicon wafers with Ultra Pure Water Spray

The high pressure characteristics inside ultrafine bubbles were utilized to experimentally verify the effect of pressure waves on removing small particles on solid surfaces. It was found that all small particles above 1 micron were removed, and the proportion of washable areas reached 92%.

3.Direct benefits brought by the system

The flow of nanobubbles in the system, which carry negative charges and can release free radicals, can effectively remove existing dirt and prevent biofilm accumulation, thereby improving the efficiency of the water tower and bringing the following advantages:

1.Reduce pipeline scaling

2.Reduce pipeline corrosion

3.Maintain clean water quality

4.Reduce the demand for chemicals.

5.Improving heat transfer efficiency can save customers up to 30% of energy costs

6.Extend the service life of cooling towers

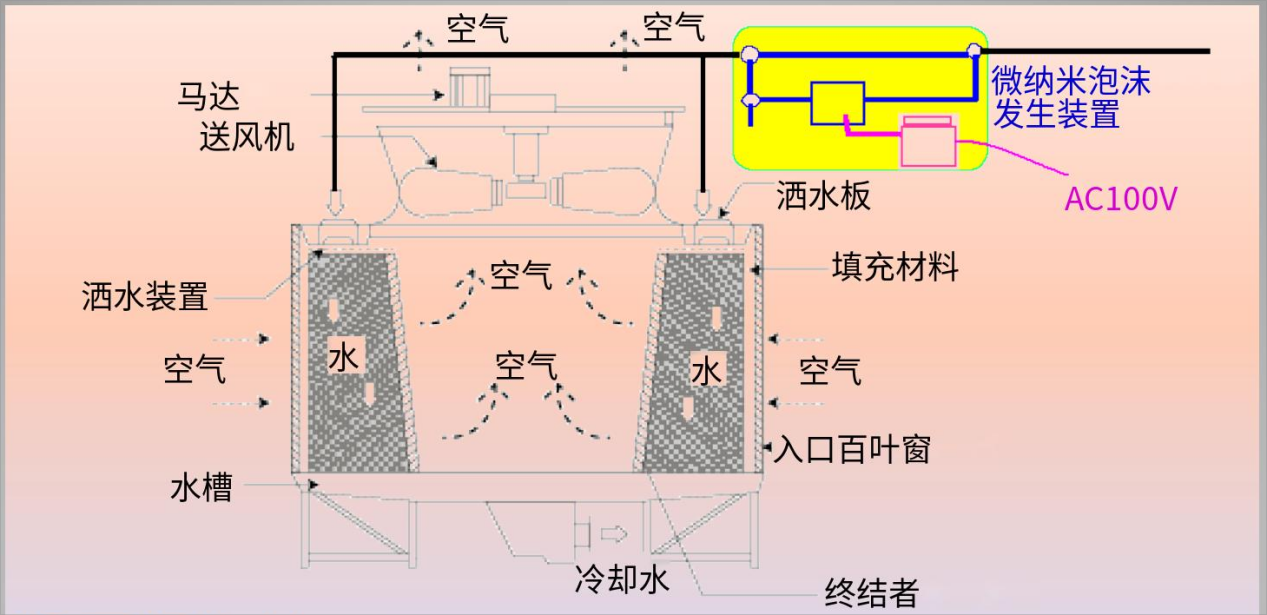

4.Introduction to the specialized nanobubble equipment for cooling systems developed by JMFILTEC

The chemical free circulating water treatment system comes from technical experts in global hydraulic cavitation treatment solutions, developed by Zhejiang Jianmo Technology Co., Ltd. for micro oxidation and scale removal equipment. This technology has passed multiple patents. We provide proven solutions for pipeline, heat exchanger, and gas-liquid exchange interface treatment systems, which can maximize equipment operation efficiency, safety, and reliability.

The advantages of this system for evaporative condensers include low cost, environmental friendliness, providing clean water, and no need for chemical agents,

Advantages for cooling towers: 50% reduction in water replenishment, 50% reduction in sewage discharge, inhibition of fouling, biological pollution, and corrosion.

Used for hot water pipelines, it can solve the problem of scaling in hard water pipelines.

This device has been validated for over 3 years in multiple industries.

1、Solved the pollution problem of ultrafiltration membranes and reverse osmosis membranes in the desalination project.

2、The application in sewage treatment MBR and mine water treatment MBR projects significantly increases the flux of ultrafiltration membranes.

3、In the water plant project, after adopting anti clogging and descaling devices, the flocculation process with flocculants has been eliminated, producing fully green and chemical free drinking water, significantly reducing operating costs.

4、In the cooling tower descaling test, in addition to significantly reducing fouling, the fouling of the heat exchanger was also resolved. The technology of its micro oxidation descaling system with silicon carbide filtration system has been proven to be effective in killing algae, oxidizing organic matter, removing calcium and magnesium ion fouling, and slowing down corrosion, completely replacing traditional water treatment methods. It covers the water quality range of membrane treatment, drinking water treatment, hot water, freezing, process cooling, and HVAC (HVAC).

The integrated solution for chemical free circulating water treatment system effectively controls scale, corrosion, and microbial contamination, while providing chemical free water flow that can be recycled for drinking water applications.

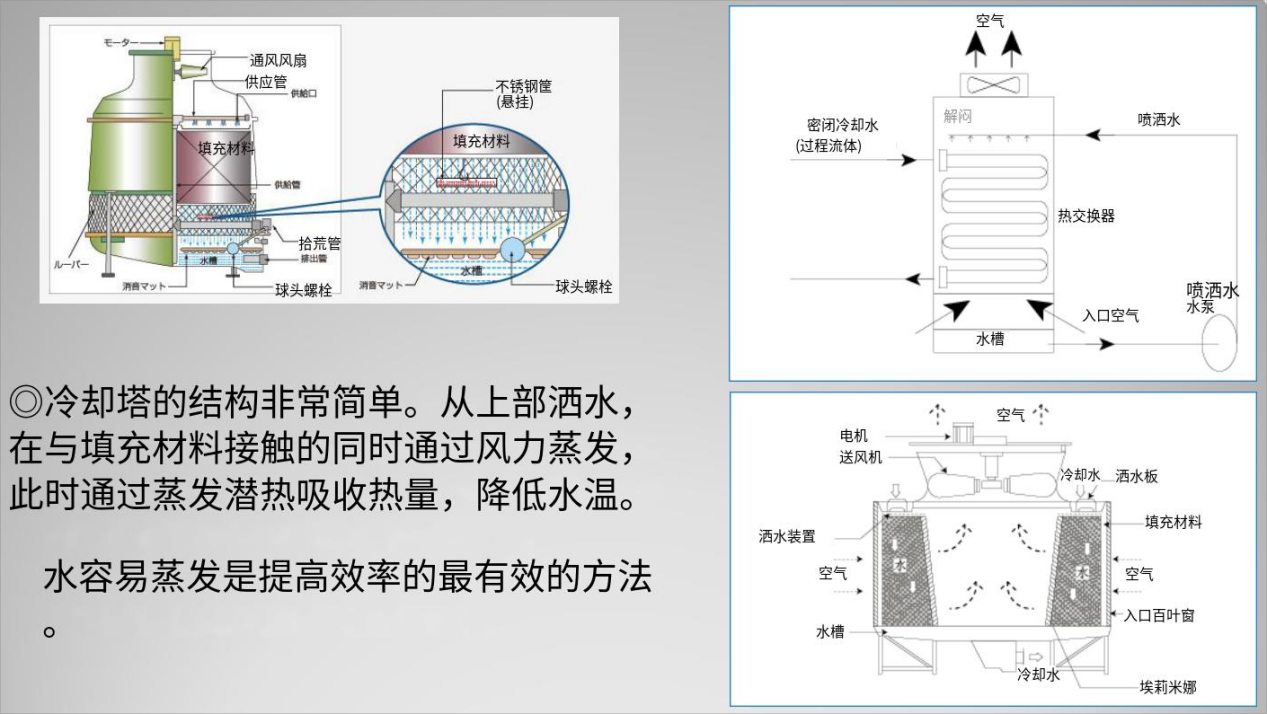

5.Working principle

Chemical free circulating water treatment system. Nanobubbles are generated through cavitation, which dynamically form and collapse in liquids. Bubbles collapse through intense processes, producing hydroxyl groups. Due to the internal pressure of nanobubbles reaching over 25mPa, nanobubbles act like sand, rubbing against the flowing pipes to remove dirt. Meanwhile, due to its hydroxyl group, it can oxidize organic matter, kill bacteria, viruses, and algae. When completely collapsed, the temperature of the vapor inside the bubble may be several thousand degrees Fahrenheit, and the pressure may be several hundred atmospheres, releasing enough energy to destroy bacteria.

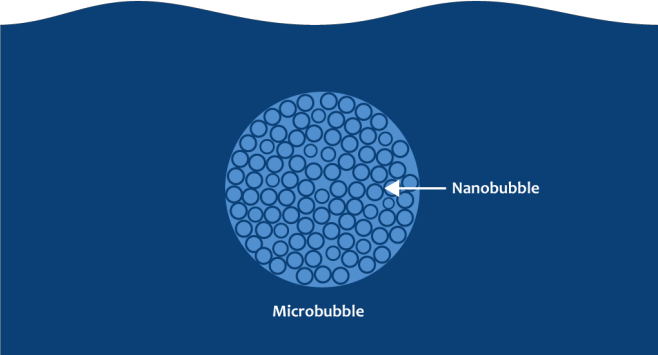

The chemical free circulating water treatment system accelerates water through the nozzle while deflecting, generating extremely high centrifugal force. The pipe wall is covered with our self-developed nanoscale silicon carbide film, and compressed gas is cut through the film to fully mix the gas and water. By high-speed rotation, a vacuum is generated inside the cavitation tube, where bubbles are cut to form nanoscale bubbles. This process utilizes the energy of the cavitation process and directs the energy towards the water flow relative to the material surface. This energy control is the core of the system used to control fouling and corrosion. This technology can achieve the lowest energy consumption in the industry, with a head loss of 3-8 meters for the entire system.

Advantages of Chemical Free Circulating Water Treatment Systems

①Chemical free circulating water treatment system to suppress fouling

1/32 inch of dirt can reduce energy efficiency by 30%. In the cooling water system, as the water temperature increases, calcium will precipitate from the solution and form dirt on the surface of the heat exchanger. The chemical treatment method attempts to retain calcium ions in the solution to prevent the formation of calcite scale, which increases energy consumption and cost. The chemical free circulating water treatment system increases the pH value of the circulating water, making it difficult for calcium carbonate (CaCO3) to dissolve. As bubbles form and collapse in the cavitation chamber, kinetic energy and local temperature drive calcium carbonate to form non adhesive CaCO3 solids, which attract dissolved calcium and carbonate ions and then filter them out of the water flow.

②Corrosion inhibition in chemical free circulating water treatment systems

During the water flow collision process in the system processing room, a strong vacuum (27.5-29.5 "Hg) area is formed, which separates dissolved CO2 from the water and helps maintain the pH value in an alkaline environment. Normally, corrosive chemicals are needed to treat dirt and bacteria, but they are not required in chemical free circulating water treatment systems. This system inhibits bacteria and helps prevent any localized corrosion caused by microorganisms, commonly known as Microbial Corrosion (MIC). This system uses an integrated filtration system to remove solid particles from the cooling water to maintain equipment surface cleanliness. This filtration system is a standard configuration for every chemical free circulating water treatment program.

③Chemical free circulating water treatment system inhibits bacteria

The extremely high pressure and high temperature generated by controlled hydraulic cavitation can physically damage bacteria and microorganisms. Microorganisms and bacteria can develop resistance to traditional chemical agents, requiring frequent adjustment of treatment methods. However, using a chemical free circulating water treatment system does not have this concern - bacteria cannot change or tolerate physical stress when passing through the treatment chamber of the system.

6.System composition

A chemical free circulating water treatment system is very convenient to install, just by opening a bypass, including a side flow connection to the inlet of the equipment, a side flow connection to the outlet of the equipment, and connection to the collection tank or water tank of the cooling tower, evaporative condenser, air scrubber, or liquid cooler. In a bypass, water passes through the system treatment room and returns to the cooling system's sink or collection tank through the bypass. Of course, matching filters can also be added to remove the precipitated calcium carbonate along with other residues that can cause pollution and lead to microbial growth. The efficient sink cleaning system guides dirt and residue to the inlet of the filter, maintaining the cleanliness of the cooling water system.

Note: Due to its bypass structure, even if a malfunction occurs, it will not have an impact on the entire device

7.Application cases

(1)Case study of JMFILTEC's chemical free circulating water treatment system

1)1)JMFILTEC's 240 ton cooling tower is equipped with a chemical free circulating water treatment system, which can clean up the dirt that has been running for nearly a year in just one month. The water change cycle is extended by more than half, reducing water consumption and environmental impact, as well as reducing employee safety issues. The outlet temperature of the cooling water has significantly decreased, and no algae growth has been observed. The energy consumption has been net reduced by 3kW:

In addition, a conductivity controller has been installed on the return flow of the main collection tank, and a corrosion hanging bracket has been installed to detect the corrosion rate of different metals. During the first startup of the system, the condenser was subjected to excellent passivation treatment. When the system is passivated and operated according to requirements, the results can meet all expected requirements:

a.Corrosion rate lower than industry standards: low carbon steel and galvanized steel<3.0mpy; 304 stainless steel<0.03mpy.

b.b.Microbial growth has also been well inhibited; Compared to the old chemical treatment system used earlier, the aerobic bacterial count (total colony count) has decreased by 80% (CFU/ml). Through multiple visual observations, no dirt was generated.

c.c.Compared to conventional chemical treatment methods, users have achieved water savings of over 1000m ³ per year. The annual cost savings exceed 100000 RMB, and the investment return period of the entire project is 12 months.

(2)Jinhua Yonghe Treatment Cooling Water (200m ³/hr)

Project Purpose:

Reduce and/or avoid the chemical treatment of cooling tower water in the factory refrigeration system, reduce the discharge of chemicals into the environment, and improve work safety by reducing the treatment of harmful substances.

Project outcome:

1)After installing the chemical free circulating water treatment system into the refrigeration cooling tower system, the following results were obtained:

2)Avoid using toxic and harmful chemical treatment agents (fungicides, algae removal agents, and corrosion inhibitors) in the refrigeration and cooling tower system.

3)The water consumption of the evaporative cooling tower has been reduced by 40%, and it has had an impact on the inflow and domestic sewage of the factory.

4)Reduce the amount of softened water used in the cooling tower, thereby reducing the amount of softener used.

5)Improve the working environment for workers.

6)The factory saves about 120000 RMB annually.

7)The return period of this project is less than one year.